JIepu Die-Cutting VHB Tape

| VHB Tape Brand | 3M, Tesa, Nitto |

| Tape thickness | 0.2mm~2.3mm |

| Tape color | White ,black , gray , transparent |

| Temperature resistance | 25° – 160° |

| Advantage | Better visvous lasting |

| Heat-Resistant | |

| Waterproof |

Yout Best Die-Cutting VHB Tapes Manufacturer

- For more than 20 years, Jiepu has been providing high-quality VHB Tapes Die-Cutting Solution

- ISO9001 certified, any size, style, design, color can be customized to meet your needs

- Provide excellent design for your 3M VHB Tapes Die-Cutting

- VHB Tape Feature

- Application Overview

- Material Insights

- VHB tape is known for its strong stickiness, replacing screws or welding.

- It sticks well to metal, plastic, glass, and composite materials.

- It performs great in high heat and humidity without losing its grip.

- VHB tape resists UV rays and chemicals, lasting long in tough conditions.

- Its flexibility absorbs shock and vibrations, protecting connected parts.

- Handles short-term heat up to 230°C, ideal for high-temp environments.

- Its stretchy material reduces vibrations, improving product stability and reliability.

- VHB tapes are UL GREENGUARD certified, meeting strict environmental standards.

Jiepu, with years of die-cutting experience, offers solutions using VHB Tape, a high-performance adhesive tape developed by 3M, known for its strong bonding and versatility.

- Strong Adhesion: VHB Tape provides powerful bonding, often replacing screws and welding in various applications.

- Surface Compatibility: It works on many surfaces, including metal, plastic, glass, and composites, making it highly versatile.

- Heat and Humidity Resistance: VHB Tape performs well in both high temperatures and humid conditions, ensuring strong adhesion even in tough environments.

- UV and Chemical Resistance: It resists UV rays and chemicals, making it suitable for outdoor and industrial environments.

- Shock and Vibration Absorption: VHB Tape absorbs impacts and vibrations, protecting the attached parts.

- Design Flexibility: It can bond different materials together, allowing for creative and stunning designs in construction and other industries.

In industries like construction, automotive, electronics, and appliances, VHB Tape offers a reliable, clean, and efficient alternative to traditional bonding methods. It is used to secure glass panels, automotive parts, electronic components, and home appliances, providing durability, flexibility, and ease of application.

Custom Die-Cutting with VHB Tape

At JIEPU, we offer customised die-cutting solutions designed to fit your unique requirements. Whether you’re working in automotive electronics, security, or other sectors, we provide high-precision, high-quality results. We offer a variety of materials, including VHB Tape, which provides strong, durable bonds for a range of applications.

From personalised designs to accurate cutting and fast delivery, JIEPU ensures flexible solutions for both small and large-scale production. Let us help you improve product quality, reduce costs, and speed up time to market.

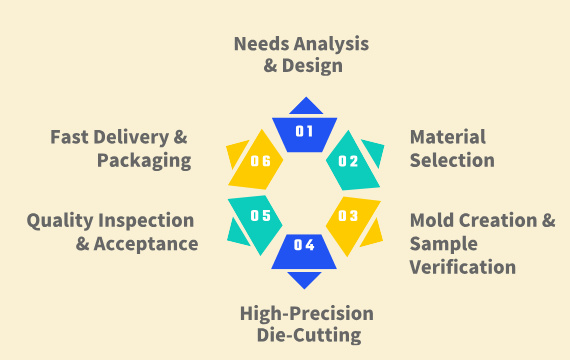

Die-Cutting Process for VHB Tape

We specialise in die-cutting VHB Tape, a high-bond adhesive material known for its excellent strength and flexibility.

The process begins with selecting the right VHB Tape, followed by careful inspection to ensure quality.

We then design precise die-cutting moulds, taking into account the tape’s strong adhesive properties.

Using flat-bed or rotary die-cutting methods, we ensure accurate shapes and clean edges, while maintaining the tape’s unique bonding capabilities.

Certified VHB Tape Die-Cutting Services

Jiepu offers VHB Tape die-cutting services that meet ISO 9001, ISO 14001, and IATF 16949 standards.

Our products are high-quality, eco-friendly, and perfect for industries like automotive.

VHB Tape provides strong bonding, durability, and invisible mounting, making it an ideal choice for clean, secure, and long-lasting applications.

We offer customised solutions for your specific needs.

Requesting Samples and Getting a Quote for VHB Tape

At Jiepu, with over 20 years of experience in die-cutting, we simplify the process of getting the right VHB Tape for your needs. Here’s a straightforward guide on how it works:

1. Share Your Requirements

Tell us the size, thickness, and adhesive strength of the VHB Tape you need.

2. Request Samples

You can request samples to test the tape’s performance before placing a full order. We’ll create a sample based on your drawings or requirements.

3. Confirm Drawings

We’ll check if your drawings are clear and if the materials can be easily sourced. We prefer to use standard materials for a smooth production process.

4. Process Analysis

We will assess the production method and ensure it fits your needs, including checking the complexity of cutting and any hole placement.

5. Product Quote

Once we have all the details, we’ll provide a quote. Keep in mind that costs vary depending on the material, processes, and whether extra steps like additional backing paper are needed.

6. Sample Production and Testing

We will make the sample and let you test it to ensure it meets your requirements. We can also offer customisation, such as adding fabric backing or heat treatment.

7. Mass Production

Once the sample is approved, we’ll start bulk production. We will schedule production based on your order quantity and delivery timeline.

8. Quality Control and Certification

We will conduct strict quality checks to ensure that the tape meets size accuracy, adhesive strength, and any necessary certifications like RoHS.

9. After-Sales Service

We offer complete support to ensure your satisfaction, including help with any issues after the product is delivered.

10. Storage Conditions

For long-term use, VHB Tape should be stored in a controlled environment to maintain its stability and performance.

11. Quotation Process

The quote includes all costs, such as material costs, production costs, and other expenses to ensure transparency.

12. Laser Cutting Technology

We use laser cutting for precise cutting of materials, especially for 3M materials, allowing for accurate shapes and designs.

13. Customisation Services

We can offer customisation of the VHB Tape, including lamination or combining with different types of foam, according to your specifications.

By following these steps, you can ensure that the VHB Tape you receive will meet your specific needs for performance, quality, and compliance.

VHB Tape has an extremely strong adhesive. It’s made with a high-performance acrylic adhesive that creates a powerful bond.

The tape’s unique foam core has both sticky liquid and elastic solid properties, making it very versatile.

The sticky part allows the adhesive to fill tiny surface gaps, creating a strong hold. Its elastic qualities help it absorb movement, making it ideal for surfaces that expand or contract.

This strength and flexibility stay consistent from -40°C to 90°C, making VHB Tape reliable in many conditions.

At Jiepu, we also offer die-cutting services for precise applications of such materials.

VHB Tape is suitable for bonding plastic materials. Its modified acrylic adhesive works well with a variety of surfaces, including different types of plastics, metals, and glass. This tape is designed to provide strong adhesion to both high and low surface energy materials. With its versatility, VHB Tape is a reliable choice for plastic bonding.

At Jiepu, we offer die-cutting services to provide customised solutions tailored to your needs.

VHB Tape typically does not leave any residue after bonding.

According to official 3M information, the tape can be removed without leaving any adhesive behind and will not damage the bonded materials.

VHB Tape is generally not corrosive to materials or surfaces. According to 3M, the tape is chemically resistant and remains stable in various environments, including exposure to UV light and temperature changes. It is also safe to use on metals and most plastics without causing any corrosion. This shows that VHB Tape is designed with broad compatibility in mind, making it a safe and non-corrosive bonding solution.

At Jiepu, we offer die-cutting services for materials like VHB Tape to meet your specific needs.