Jiepu Die-Cutting Neoprene Foam

- For more than 20 years, Jiepu has been providing high-quality Die-Cutting Neoprene Foam

- Low MOQ to Support Your Business

- ISO9001 certified, any size, style, design, color can be customized to meet your needs

- Quick Samples from China

- Product Details

- Application Overview

- Material Insights

- Weather Resistance: Neoprene Foam holds up well in various climates and harsh conditions.

- Chemical Resistance: It resists many chemicals, making it great for sealing against chemical exposure.

- Wide Temperature Range: Works in temperatures from -35°C to 130°C (-31°F to 266°F).

- Oil Resistance: Neoprene Foam is resistant to oil, second only to nitrile rubber.

- Insulation: With low thermal conductivity, it provides excellent heat insulation.

Jiepu, with years of experience in die-cutting, has provided services in various industries, and now introduces Neoprene Foam and its key characteristics:

- Water Resistance & Insulation: Neoprene Foam is perfect for making wetsuits and life jackets because it keeps you warm while being waterproof.

- Medical Uses: It’s used in medical products like braces and bandages, as it provides cushioning and absorbs impact.

- Outdoor Gear: Its ability to withstand weather and chemicals makes it ideal for rain gear, gloves, and boots.

- Automotive Industry: Neoprene Foam is used for seals and vibration control in cars, keeping things stable even in tough environments.

- Construction: It’s applied in buildings as sealants and soundproofing, staying durable without cracking or ageing.

- Footwear: Neoprene Foam is used in shoe insoles, adding comfort and cushioning to sports shoes.

- Sports Equipment: It’s used in mats and flooring for gyms and sports fields, providing shock absorption.

- Everyday Items: Neoprene Foam is found in items like insulated cup holders and fishing pants, taking advantage of its water-resistant and insulating properties.

For die-cutting customers, Neoprene Foam is highly valued for its durability, weather resistance, flexibility, and easy processing, making it a great material for custom-shaped products.

Jiepu, with years of die-cutting experience, introduces Neoprene Foam and its key features:

- Weather Resistance: Neoprene Foam is durable in outdoor environments, resisting UV rays, oxygen, and ozone.

- Chemical Resistance: It can withstand exposure to many chemicals, making it ideal for harsh environments.

- Oil Resistance: This foam is perfect for use in applications where it comes into contact with oils.

- Wear Resistance: Neoprene Foam is durable against friction and wear, making it suitable for heavy-use applications.

- Elasticity & Tear Strength: It offers great elasticity and tear resistance, even in extreme conditions.

- Electrical Insulation: Neoprene Foam is a good electrical insulator, ideal for electronic devices.

- Flame Resistance: It meets specific flame retardant standards, adding safety to certain applications.

- Environmentally Friendly: The material is non-toxic and suitable for eco-conscious projects.

For die-cutting, Neoprene Foam’s properties allow precise cutting to create custom seals, gaskets, and insulation products, ensuring both performance and appearance meet customer needs.

Custom Die-Cutting with Neoprene Foam

At JIEPU, we offer tailored die-cutting solutions designed to meet your specific requirements. Whether you’re working in automotive electronics, security, or other industries, we ensure high-precision and high-quality results. We use a variety of materials, including Neoprene Foam, which is ideal for providing excellent cushioning, sealing, and resistance to wear.

With a focus on personalised design, accurate cutting, and fast delivery, our services support both small and large-scale production. JIEPU helps you enhance product quality, reduce costs, and speed up time to market, ensuring you stay competitive in your industry.

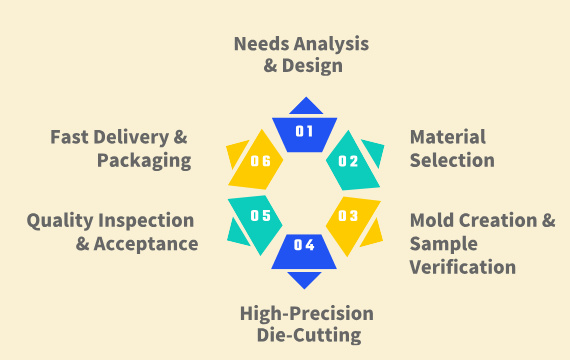

Die-Cutting Process for Neoprene Foam

We specialise in die-cutting Neoprene Foam, a material known for its excellent durability and flexibility.

The process starts with selecting high-quality foam, followed by precise mould design to ensure clean, smooth cuts.

We then use either flat-bed or rotary die-cutting techniques depending on the foam’s thickness.

These methods guarantee accuracy, ensuring that each piece meets the required shape and size while maintaining the material’s unique properties.

Requesting Samples and Getting a Quote for Neoprene Foam

At Jiepu, with over 20 years of experience in die-cutting, we make it simple for you to get the right Neoprene Foam for your needs. Here’s how the process works:

1. Share Your Requirements

Let us know your specific needs, such as thickness, hardness, size, and shape.

2. Request Samples

You can ask for samples to test the foam before making a decision. We’ll create an initial sample based on your drawings or requirements.

3. Confirm Drawings

To ensure smooth mass production, we’ll confirm if your drawings are clear and if materials are available. It’s helpful if you can provide 2D designs.

4. Process Analysis

We’ll check if the production process is feasible and the difficulty of cutting the foam. This includes ensuring the right method for locating holes.

5. Product Quote

Once we have all the details, we’ll provide a quote. Costs can vary depending on the material, production methods, and if any extra steps are required.

6. Sample Production

Samples are an essential part of the process—they help confirm your order and give you a chance to approve the product before mass production.

7. Quality Control and Packaging

Once we have the final product, we’ll perform quality checks to ensure size accuracy, shape consistency, and that the foam meets your needs. The foam will then be carefully packaged for delivery.

8. Customisation

We offer customisation to meet your specific size, shape, or functional needs.

9. Strict Quality Control

We apply strict quality control to ensure the product is up to standard and compliant with RoHS and safety regulations.

10. Storage Conditions

For long-term use, Neoprene Foam should be stored in a stable environment to preserve its properties and performance.

11. Quotation Process

The final quote includes all costs, from raw materials to production, and ensures all factors are considered.

12. Order Information

Once the order details are confirmed, we’ll review the quantity and production feasibility and prepare the necessary documents.

By following these steps, you can be confident that your Neoprene Foam product will meet your specific performance, quality, and compliance needs.

Neoprene foam, also known as polychloroprene foam, is a flexible, durable material made from synthetic rubber. It’s known for its ability to withstand tough conditions, making it ideal for many uses.

The foam is very tough and resists tearing or wearing down easily, which means it lasts a long time. It’s flexible even in extreme temperatures, so it can be used in both hot and cold environments.

It also resists water, oils, and many chemicals, making it perfect for industrial and outdoor applications.

Neoprene foam is great at providing thermal insulation, which makes it useful in automotive, construction, and electronics, where temperature control is important. Its closed-cell structure means it doesn’t absorb water, unlike open-cell foams.

It’s also comfortable and soft, making it a popular choice in protective gear and automotive seals. Neoprene foam absorbs shocks well, which makes it ideal for use in automotive padding, electronics packaging, and other protective applications. Plus, it has some resistance to UV light, helping it last longer when exposed to sunlight.

Neoprene foam can be shaped easily into different products, and while it’s not biodegradable, it’s more environmentally friendly than some other materials.

At Jiepu, we provide die-cutting services for a wide variety of materials, including Neoprene foam, to help create custom products tailored to your needs.

Neoprene foam’s wear resistance is influenced by several key factors.

The hardness of the material plays a big role in how well it withstands wear and tear. Harder materials are generally better at resisting scratches and damage.

The structure of the foam also matters; finer-grained materials are typically more durable because they have a smoother surface, which reduces friction.

The density of the foam is another important factor. Higher-density materials are more resistant to wear because their molecules are packed more tightly.

Additionally, adding certain chemicals, such as hard particles or alloys, can enhance the foam’s strength and wear resistance.

The environment in which the foam is used affects its durability. For example, exposure to high temperatures, pressure, or chemicals can lower wear resistance.

Neoprene foam is also highly resistant to oil, which makes it ideal for automotive components and electronic devices where durability is essential.

Its resistance to weathering and chemical breakdown makes it a great choice for outdoor equipment and construction materials.

In industries like automotive and consumer electronics, Neoprene foam is used for sealing, padding, and insulation, where wear resistance is crucial for long-lasting performance.

In summary, Neoprene foam’s wear resistance comes from its hardness, fine structure, high density, and chemical stability, making it ideal for use in automotive and consumer electronics applications. Jiepu offers die-cutting services to help create tailored Neoprene foam products for these industries.

Neoprene foam can typically withstand temperatures between -40°C and 100°C, depending on the specific type and use.

Some Neoprene foams are designed for even lower temperatures, down to -56°C, and can handle higher temperatures up to 93°C.

For general use, most Neoprene foam products perform well within a range of -40°F (-40°C) to 158°F (70°C).

The material’s softening point is around 80°C, and it begins to break down at temperatures between 230°C and 260°C.

At Jiepu, we can help provide tailored die-cutting solutions for your needs, ensuring the right material for your project