Quality Die-Cutting Electrically Conductive Tapes Manufacturing

- Partner with Us for Your Next Die-Cutting Electrically Conductive Project

- IATF 16949:2016 Certification

- 3-day rapid production of samples

- Low MOQ to Support Your Business

- Product Details

- Application Overview

- Material Insights

- Electrically conductive tapes ensure good electrical conductivity for signal transmission and grounding.

- EMI and RFI Shielding tapes block electromagnetic and radio frequency interference, protecting devices from disruptions.

- Soft texture allows for easy cutting and shaping for manual or automated use.

- Electrically conductive tapes stick firmly to metal surfaces for stable electrical connections.

- They resist chemicals and outdoor weather, keeping performance intact.

- Suitable for high-temperature environments without losing functionality.

Jiepu, with years of die-cutting experience, provides solutions for various applications of Electrically Conductive Tapes.

- Consumer Electronics: Used in smartphones and laptops to shield against electromagnetic interference (EMI) and improve grounding.

- Automotive Industry: Used for EMI shielding and grounding in vehicles to protect electronic systems from interference.

- Telecommunication Infrastructure: Applied in data centres and communication stations to shield cables and devices from signal interference.

- Aerospace and Defence Electronics: Provides shielding and grounding for sensitive equipment in high-performance environments.

- Medical Equipment: Used to connect and secure sensors in medical monitoring devices, requiring good flexibility and biocompatibility.

- Aluminum Foil Tape: Known for its strong conductivity and durability, it’s widely used in aerospace and mechanical industries for shielding wires and electronic components from interference.

- Copper Foil Tape: Offers excellent shielding against electromagnetic interference (EMI), especially useful for protecting cables exposed to the elements and blocking radio or magnetic waves.

- Nickel/Copper Foil Tape: Combines nickel and copper to provide conductivity in multiple directions, often used for grounding and EMI shielding in sensitive electronic equipment.

- Conductive Foam Tape: Made with conductive foam, it shields against interference while filling gaps in casings, providing protection for delicate components.

- Conductive Non-Woven Tape: Offers quick adhesion and adapts well to uneven surfaces, ideal for applications requiring reliable contact on irregular shapes.

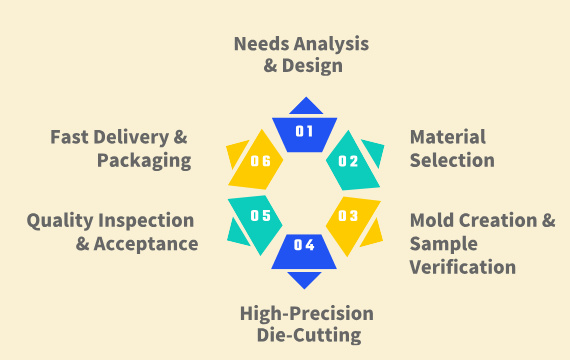

Die-Cutting Process for Electrically Conductive Tapes

We select high-quality materials, such as conductive foils and films, tailored to meet specific conductivity and durability requirements.

Each material undergoes strict quality checks to guarantee defect-free performance.

Using advanced moulding techniques like laser cutting, we create sharp and durable dies for accurate cutting.

Whether flatbed or rotary methods are used, Jiepu ensures precise shapes and sizes, meeting diverse product demands with efficiency.

Certified Die-Cutting Services You Can Trust

At Jiepu, our die-cutting services meet globally recognised standards, ensuring top quality and sustainability.

With ISO 9001 for quality management, ISO 14001 for environmental care, and IATF 16949 for automotive excellence, we guarantee precision and reliability.

Our Electrically Conductive Tapes combine strong adhesives with conductive materials like foam, woven fabric, and aluminium, offering superior bonding and conductivity even in tough environments.

Sample Request and Quotation Process for Electrically Conductive Tapes

At Jiepu, we’ve been perfecting the art of die-cutting for over 20 years. Let us guide you through the simple steps to get your Electrically Conductive Tapes just right.

Understanding Your Needs We start by chatting about what you need for your conductive tapes—like size, thickness, and where you’ll use them.

Sample Requests You can ask for samples to test out. We make a first draft based on your ideas or drawings.

Design and Production Check We make sure it’s all good to go for mass production, using reliable materials and making sure everything’s in place for a smooth process.

Pricing Made Simple We give you a price that covers everything, from materials to making it, and a bit extra for us. It’s all out in the open.

Testing and Tweaking We make you a sample to test, and if it needs a backing or some heat treatment, we can do that too.

Moving to Mass Production Once you’re happy with the sample, you place an order, and we start making more. We work around your schedule.

Quality Control and Certification We check everything thoroughly and have the right certificates to show our products are safe and eco-friendly.

After-Sales Service We’re here for you even after you’ve got your order. Any issues? Just give us a call.

Storage Conditions Keep your conductive tapes in the right temperature and humidity to keep them in top shape.

Special Requests If you need something extra, like a specific temperature range or shielding effect, just tell us. We’ll make it happen.

Eco-Friendly and Compliant Our tapes are RoHS compliant, meaning they’re safe for the environment and free from harmful stuff.

Custom Services We offer custom services, from laminating to sticking different types of foam, all made to your liking.

By following these steps, you get conductive tapes that fit your needs perfectly. Each step is designed to ensure your product performs well, meets quality standards, and is compliant with regulations.

Electrically Conductive Tapes are special tapes designed to conduct electricity.

They are made from a conductive backing material and adhesive, allowing them to handle tasks like grounding, shielding against electromagnetic interference (EMI), and protecting against static discharge (ESD).

These tapes are commonly used in industries like automotive, aerospace, defence, medical, and telecommunications.

They can transfer electrical signals in devices and are compatible with materials such as foam, fabric, aluminium, or copper to suit different needs.

Electrically Conductive Tapes perform well under tough conditions, maintaining strong adhesion and conductivity.

They are durable, resist tearing, and are easy to integrate into production processes.

At Jiepu, we specialise in die-cutting services for materials like conductive tapes, tailored to your specific application needs.

Electrically conductive tape works by using conductive materials that allow electric current to pass through. Here’s a simplified explanation:

The tape has a conductive layer, often made of materials like copper, aluminium, or conductive carbon. This layer creates a path for electricity. The adhesive used is also conductive, enabling the tape to form an electrical connection when applied to surfaces.

It helps in shielding against electromagnetic interference (EMI) by directing unwanted currents to the ground. It can also provide grounding for parts, protect sensitive components from static electricity (ESD), and even transfer electrical signals in specific setups.

To ensure proper function, the surfaces it sticks to should be clean and smooth for good electrical contact. Environmental factors like humidity or temperature changes can affect its performance.

At Jiepu, we offer die-cutting services for custom conductive tape solutions to suit your needs.

Electrically conductive tapes come in various types, each designed for specific uses. Here’s a simple breakdown:

Single-Sided Conductive Tape uses a conductive material on one side for grounding or shielding, making it great for light and flexible needs like display assembly.

Double-Sided Conductive Tape has conductive adhesive on both sides to connect two surfaces. It’s ideal for tasks like bonding and grounding in electronics.

Shielding Conductive Tape blocks electromagnetic interference (EMI) and ensures clean signals by redirecting interference to the ground.

Conductive Foam Tape combines conductivity with cushioning, offering vibration resistance and gap filling in electronics.

Heat-Activated Conductive Tape activates at high temperatures for strong bonds and excellent conductivity in challenging conditions.

Copper Foil Tape is highly conductive and perfect for shielding and static prevention, often used in sensitive electronics or temperature insulation.

Non-Woven Conductive Tape and Conductive Fabric Tape are flexible and easy to cut, making them practical for grounding and shielding tasks.

At Jiepu, we offer tailored die-cutting solutions for all these types, ensuring the tape fits perfectly for your specific needs.

According to our Jiepu’s many years of experience in die-cutting materials. when choosing conductive tape for your electronics, there are a few key points to keep in mind:

- Conductivity Needs: Match the tape’s conductivity to your product’s requirements. For high-conductivity demands, consider tapes with silver or copper fillers.

- Adhesion And Shielding: If you need both sticking power and shielding, dual-sided conductive tapes like tesa® ECT 6025x/6026x series can be a good choice.

- Durability: For tough environments, opt for tapes with strong environmental stability, such as 3M conductive tapes, which are reliable under challenging conditions.

- Flexibility And Thickness: Thin, flexible tapes work well in compact designs. Choose a thickness that suits your space and application.

- Ease Of Use: Pick tapes that are easy to cut and fit into automated assembly processes, such as 3M-9703 Z-axis conductive tape.

- Special Features: For unique needs like Z-axis conductivity, specific tapes designed for this purpose are ideal.

- Cost: Balance performance and budget. High-performance tapes may cost more but can be essential for demanding tasks.

- Supplier Support: Work with a supplier offering technical assistance and customisation options to meet your specific needs.

- Compliance: Ensure the tape meets safety and regulatory standards like RoHS.

- Testing: Always test before finalising to ensure the tape performs as required in real-world use.

The electrical performance of conductive tape depends on a few key factors:

The conductive particles inside the tape, such as silver, copper, or graphite, create its conductivity. The size and shape of these particles also affect how well the tape conducts electricity.

The way these particles form pathways is essential. When pressed together, they create channels that allow electricity to flow.

The resin holding the particles together plays a role too. For example, epoxy resins are popular because they’re strong and can cure at lower temperatures.

Environmental factors like temperature and humidity can impact performance, so the tape should be tested under the conditions where it will be used.

At Jiepu, we offer die-cutting services to customise materials like conductive tape for your specific needs.