Jiepu Die-Cutting Mylar Film System Benefit

- Leading Die-Cutting Mylar Film Manufacturer, Producing Die-Cutting Mylar Film for Your Industry

- Provide excellent design for your Die-Cutting Mylar Film

- Affordable Die-Cutting Mylar Film for All Industries

- 3-day rapid production of samples

- Product Details

- Application Overview

- Material Insights

- The mylar film is a great electrical insulator, widely used in electronics like capacitors.

- The film resists many chemicals, making it highly durable against chemical corrosion.

- Mylar film offers exceptional strength and toughness, with high tensile strength in both directions.

- It maintains performance in temperatures from -70°C to 150°C without degradation.

- The film resists punctures and abrasions, perfect for tough and wear-resistant applications.

Jiepu, with years of die-cutting experience, has provided services in various industries using Mylar Film, a material known for its durability and versatility:

- Electronics Industry: Mylar Film is used for electrical insulation, as a protective layer in solar panels, and for precision patterns in LED displays due to its strong insulation properties.

- Packaging Industry: Mylar Film is used in food, drug, and cosmetic packaging, offering excellent protection and helping to extend shelf life due to its low permeability.

- Solar Industry: Mylar Film is ideal for solar panels due to its weather resistance and long-lasting performance.

- Flexible Electronics: The flexibility and strength of Mylar Film make it perfect for applications like flexible circuits and displays.

- Insulation Materials: Mylar Film is widely used in motors, capacitors, and cables for its excellent insulation, heat resistance, and chemical durability.

Jiepu, with years of die-cutting experience, introduces Mylar Film, a versatile material widely used across various industries due to its unique properties:

- Transparency and Gloss: Mylar Film is clear and shiny, making it perfect for transparent packaging, like food and cosmetics.

- Mechanical Strength: Its high tensile strength and tear resistance make it ideal for durable applications, such as electrical insulation and protective films.

- Heat Resistance: Mylar Film can withstand high temperatures without melting, making it useful in electronics for capacitor and motor insulation.

- Electrical Insulation: The material’s structure provides excellent electrical insulation, making it ideal for use in electronic devices.

- Chemical Resistance: Mylar Film resists many chemicals, maintaining its performance in various chemical environments, especially for packaging sensitive products.

- Gas Barrier: Its dense structure offers gas barrier properties, helping extend the shelf life of food by keeping it fresh.

- Reflectivity: Mylar Film can reflect light, which is useful in applications like hydroponic gardening to boost plant growth.

Custom Die-Cut Solutions with Mylar Film

At Jiepu, we provide precision die-cutting services using Mylar Film to suit your unique needs. Whether for automotive electronics, security, or other sectors, our tailored solutions ensure high-quality, accurate results. With a wide range of materials and advanced cutting techniques, we deliver efficient, cost-effective solutions to help improve product performance and reduce time-to-market. Trust us to provide flexible, reliable services for both small and large-scale production.

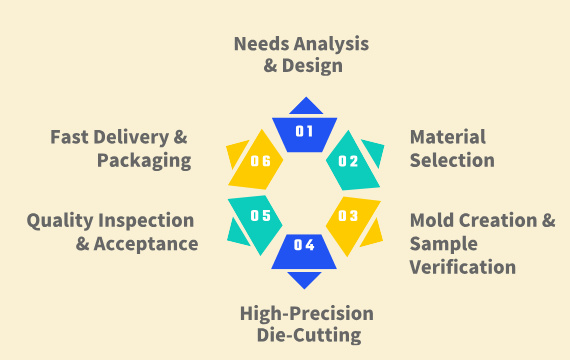

Mylar Film Die Cutting Process

Based on Jiepu’s expertise, Mylar Film, made from durable polyester (PET), is often used for its excellent insulation and heat resistance.

The process begins with selecting and inspecting the material to ensure it meets high-quality standards.

Using precision tools, the film is cut into specific shapes, either through flatbed or rotary die cutting, depending on its thickness.

For more complex needs, perforating and shaping can be added to ensure the film fits perfectly into its intended application.

Certified Die-Cutting Solutions with Mylar Film

Our internationally certified services, including ISO 9001, ISO 14001, and IATF 16949, ensure high-quality, sustainable, and reliable results. These standards reflect our dedication to precision and customer satisfaction.

Our Mylar Film is a flexible polyester material known for its smooth surface, transparency, and durability. It’s widely used for electronics insulation and industrial components like transformer coils. Fully customisable to your needs, we provide Mylar in rolls of various sizes, meeting both production and environmental standards such as ROHS compliance.

Mylar Film Die-Cutting Samples and Quotation Process

At Jiepu, we’ve streamlined the Mylar Film sample and quotation process for your convenience. Here’s a simple breakdown:

- Quotation: We calculate prices based on material, process complexity (single or multi-step), and order quantity. Quotes are tailored for different scales, from small batches to bulk production.

- Project Timeline: Quotes are delivered within 24 hours, and samples are ready within 72 hours to ensure a quick response to your needs.

- Design Updates: Any design changes are handled efficiently with proper communication and process analysis.

- Sample Preparation: We create samples using accurate drawings, material specs, and detailed dimensions. All steps are checked to meet your requirements.

- Quality Check: Our team performs precise measurements and provides inspection reports to guarantee quality.

- Sample Delivery: Samples are securely packed, shipped promptly, and tracking information is shared within 24 hours.

- Documentation: We include essential documents like material certifications, drawings, inspection reports, and technical guidelines.

- Tooling and Production: Die-cut moulds are designed and tested to meet your exact needs before scaling up production.

This process ensures every Mylar Film sample and quote is accurate, efficient, and tailored to your project. Let Jiepu help you with your die-cutting needs!

Mylar Film Has Excellent Temperature Resistance.

It Can Handle Temperatures Up To 130°C Without Issue.

Mylar® A-Type Film Stays Stable Across A Wide Range, From -73°C To 149°C.

It Can Also Withstand Temperatures As High As 200°C, Making It Ideal For Extreme Conditions.

This Material Remains Strong And Durable, Even Under Harsh Heat Or Cold.

It’s Resistant To Common Solvents, So It Works Well In Many Industries.

At Jiepu, We Offer Die-Cutting Services For Mylar, Perfect For Your Custom Needs.

Mylar Film Has Excellent Anti-Static Properties.

It Can Form A Smooth Anti-Static Layer On Its Surface, Reducing Friction And Static Buildup.

This Layer Helps To Quickly Discharge Static, Preventing Surface Voltage Issues.

The Anti-Static Additives Can Neutralise Charges, Eliminating Static Electricity.

It Offers A Wide Range Of Resistance, From 10^6 To 10^9 Ohms.

The Anti-Static Performance Stays Stable Between -20°C And 220°C, Without Loss Of Effectiveness.

It Maintains Consistent Release Force And Overall Excellent Performance.

Produced In A Cleanroom, Mylar Film Has High Purity And Is Free From Defects Like Scratches Or Bubbles.

This Makes Mylar Ideal For Applications That Require Anti-Static Properties.

At Jiepu, We Provide Die-Cutting Services To Tailor Mylar Film To Your Specific Needs.

Mylar Film Offers Good UV Protection.

Its Structure Naturally Blocks UV Light, Thanks To Groups Like Phenolic And Ketone.

This Makes Mylar An Effective UV Barrier, Blocking Nearly All UV Radiation.

In Addition, Mylar’s UV Resistance Is Further Improved When Combined With Lignin, Which Contains UV-Absorbing Groups.

With Lignin, Mylar Can Block UVB (290-320nm) And UVA (320-400nm) Radiation Very Well.

The SPF Value Of Mylar Increases When More Lignin Is Added, Showing Its Stronger UV Protection.

Overall, Mylar Film Is A Reliable Material For Protecting Against UV Damage.

Mylar Film Has Excellent Electrical Insulation Properties.

It Can Withstand Up To 7,000 Volts Of Electrical Strength With A 1 Mil Thickness.

It Also Resists Most Chemicals, Keeping Its Insulation Properties In Harsh Environments.

Mylar Maintains Its Insulation Ability In Extreme Temperatures, From -60°C To 150°C, Without Becoming Brittle.

It Meets UL Standards, With A High Thermal Rating Of 130°C, Suitable For Many Electrical Applications.

Mylar Is Widely Used In Electrical Industries, Including In Transformers, Motors, And Generators.

Its Physical Strength, Such As Resistance To Tearing And Stretching, Adds To Its Durability.

Before Leaving The Factory, Mylar Is Tested To Ensure The Highest Insulation Quality.

At Jiepu, We Offer Die-Cutting Services To Tailor Mylar Film To Your Specific Electrical Needs.

Mylar Film Has Excellent Wear Resistance.

It Is Made From Polyester, Which Provides Strong Physical And Chemical Stability, Ensuring Durability Across Many Applications.

In Electronics, Mylar Is Often Used As A Dielectric Material In Capacitors, Where It Needs To Be Both Insulating And Wear-Resistant.

Research Has Shown That Materials With Special Structures Can Have Better Wear Resistance, Like The Scaly Design Found In Some Films.

Mylar’s Wear Resistance Is Also Proven In Real-World Uses, Such As Its Role As A Protective Layer For Solar Panels, Where It Helps Prevent Damage From The Environment.

Overall, Mylar Is Highly Durable, Making It Suitable For A Range Of Industries Like Electronics And Solar Energy.

At Jiepu, We Offer Die-Cutting Services To Customize Mylar Film For Your Specific Applications.