Jiepu Custom Your Die-Cutting BISCO Silicones

- Custom BISCO Silicones Die-Cutting Solutions Tailored to Your Industry

- Fast Sample Production for Die-Cutting BISCO Silicones in Just 3 Days

- Applicable to various fields

- IATF 16949:2016 Certification

- Product Details

- Application Overview

- Material Insights

- BISCO Silicones withstand extreme temperature changes, UV rays, and ozone without degrading.

- BISCO silicone products resist mechanical fatigue and perform well over long-term use.

- BISCO Silicones comply with the toughest UL fire safety standards for protection.

- Performs in temperatures from -65°F to 400°F (-55°C to 200°C).

- Complies with RoHS and REACH, ensuring low smoke toxicity and flame spread.

Jiepu, with its expertise in die-cutting, has worked with BISCO Silicones, a high-performance material from Rogers Corporation, across multiple industries.

- Medical and Life Sciences: BISCO® MS silicone is used in seals and gaskets for biopharma, offering heat, ozone, and chemical resistance at a lower cost.

- Electronics: BISCO® silicone is used for cable insulation and electronic component packaging due to its excellent electrical insulation properties.

- Building Materials: BISCO® silicone is used for waterproof seals and thermal insulation, known for its weather resistance and durability.

- Automotive: BISCO® silicone is used in seals, hoses, and windshield seals, offering high heat and chemical resistance.

- Aerospace: BISCO® silicone is used for seals and insulation, benefiting from its high-temperature resistance.

- Cold Chain, Cushioning, and Fire Retardant Materials: BISCO® silicone is widely used in cold chain applications, cushioning, gap filling, and fire-resistant seals.

Jiepu, with years of die-cutting experience, presents the key features of BISCO Silicones, a high-performance material from Rogers Corporation, widely used across many industries.

- High-Temperature Resistance: BISCO Silicones stay stable and flexible in extreme temperatures, ranging from -60°C to +230°C, making it ideal for high-temperature environments like car engines and aerospace applications.

- Electrical Insulation: BISCO Silicones provide excellent electrical insulation, preventing the flow of electrons, making it perfect for use in cables and electronic component packaging.

- Weather Resistance: This silicone material resists UV rays, oxygen, and humidity, making it ideal for outdoor applications like solar equipment and outdoor lighting.

- Chemical Stability: BISCO Silicones resist corrosion from various chemicals, which is why it’s often used in the chemical and medical industries.

- Flexibility and Elasticity: The material’s softness and elasticity allow it to adapt to different shapes and surfaces, often used in sealing and insulation.

- Anti-Aging: BISCO Silicones retain their physical properties for a long time, offering excellent durability and longevity due to their stable chemical structure.

- Biocompatibility: BISCO MS silicone is widely used in medical and life sciences because it meets strict biocompatibility standards, ensuring safety in sensitive applications.

Custom Die-Cut Solutions with BISCO Silicones

At Jiepu, we offer customised die-cut services using high-performance materials like BISCO Silicones. Whether your project involves automotive electronics or security systems, we provide tailored solutions with precise designs, top-quality materials, and cutting-edge cutting technology. Our services help reduce costs, improve product quality, and speed up your time to market.

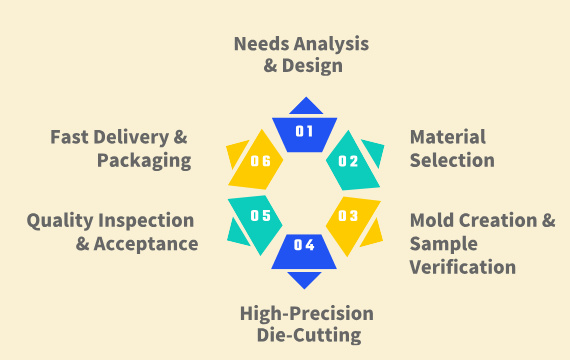

BISCO Silicones Die Cutting Process

At Jiepu, we frequently work with BISCO Silicones materials, such as silicone foam and solid silicone, known for their durability in extreme conditions.

The process begins by selecting the right material, followed by designing a precise die that suits the material’s properties.

Using either flatbed or rotary die cutting, we shape the material as needed.

Additional steps like perforating and forming ensure the product meets specific requirements, such as sealing and insulation.

Trusted Die-Cutting Services with Certified Quality

We are proud to deliver high-quality die-cutting services backed by global certifications.

Our ISO 9001 ensures reliable quality and customer satisfaction, while ISO 14001 demonstrates our commitment to protecting the environment and using resources efficiently.

For the automotive industry, IATF 16949 reflects our expertise in meeting strict quality standards.

BISCO Silicones Die-Cutting Samples and Quotation Process

At Jiepu, we’ve simplified the process of requesting samples and getting quotes for BISCO Silicones. Here’s a straightforward guide:

- Quick Response: We provide quotes within 24 hours and samples within 72 hours, keeping your project on schedule.

- Design Adjustments: Any design changes are reviewed and processed with detailed analysis and clear communication.

- Process Analysis: We ensure the feasibility of your design, check production complexity, and confirm necessary features like positioning holes.

- Accurate Quotation: Our team calculates costs based on materials, processes, and order size, offering tiered pricing for transparency.

- Sample Creation: We need precise drawings, detailed measurements, and any special notes to create a plan, ensuring smooth production.

- Quality Inspection: All samples are measured by our quality team, and a detailed report is provided.

- Fast Shipping: Samples are packed with all required documents and shipped promptly, with tracking details shared within 24 hours.

- Documentation: Essential documents, including material certifications and inspection reports, are organised and provided with your sample.

- Mould Preparation: We manage mould design, pricing, delivery timelines, and quality control.

- RFQ Support: We handle supplier evaluation, prepare RFQs, and ensure competitive pricing decisions.

- Sample Quotation Application: Detailed information, including specifications and deadlines, is prepared for precise sample pricing.

- Sample Analysis: We analyse your sample requirements to ensure a thorough understanding before quoting.

This process ensures accuracy, speed, and reliability from start to finish. Have a project? Let us simplify it for you!

To Prevent Adhesion in BISCO Silicones’ Silicone Products, Here Are Some Simple Steps:

Make sure the silicone surface is clean and dry before use. This helps reduce the chances of sticking.

Apply a release agent, like silicone oil or a special spray, on the surface. This reduces the stickiness between the silicone and other surfaces.

Store silicone products in a cool, dry place. Avoid heat and moisture as they can make the silicone more sticky.

Keep silicone products away from chemicals that could cause reactions. Some chemicals can make silicone more adhesive.

Use anti-stick papers or films between silicone products to reduce direct contact.

Regularly check the products for any sticking issues and deal with them quickly to avoid damage.

Avoid exposing silicone to high temperatures. This can soften the silicone and increase its stickiness.

If stacking silicone products, avoid heavy pressure. This can cause the bottom products to deform and stick.

Use the right tools when handling silicone. Avoid metal or hard plastic tools that can cause sticking.

If adhesion issues persist, consider replacing the silicone product to maintain its performance and safety.

At Jiepu, we offer die-cutting services to help customise silicone materials to your specific needs, improving product quality and performance.

BISCO Silicone Products Are Suitable For Electromagnetic Interference Shielding In Electronic Devices.

For example, BISCO® EC-2130 is a soft, conductive silicone material designed to reduce electromagnetic and radio-frequency interference.

This material can block more than 100 dB of interference, making it effective for protecting sensitive electronic components.

If you’re looking to customise materials for your specific needs, Jiepu offers die-cutting services to ensure you get the perfect fit.

Typically, BISCO Silicones are designed to last about two years, depending on the specific type.

If stored for too long, their performance may start to decline.

While they might still be usable after the expiry date, their effectiveness cannot be guaranteed, especially for applications with strict requirements.

It’s always best to use BISCO Silicones’ die-cut silicone products within their shelf life to ensure optimal performance.

At Jiepu, we offer die-cutting services to help customise silicone materials to your needs, ensuring you get the best results every time.

BISCO Silicone Products Are Known for Their Good Chemical Resistance.

This means they can handle contact with various chemicals without breaking down.

Their Silicone Products Are Often Used in Industries Like Food, Medical Devices, and Chemicals, Where Chemical Resistance Is Crucial.

BISCO Offers High-Performance Materials Like Porous Silicone Foam and Solid Silicone, Both of Which Perform Well in Chemical Environments.

Their Products Also Withstand UV Light, Ozone, and Common Disinfectants, Proving Their Stability in Harsh Conditions.

For Industries That Need Reliable Materials, BISCO’s Silicone Meets Industry Standards Like FDA 21 CFR 177.2600, Ensuring Safety and Durability.

BISCO Silicones Is Ideal For Thermal Management Solutions.

Their Silicone Materials Can Handle Extreme Temperatures, UV Light, And Ozone, While Withstanding Pressure And Deformation.

BISCO Silicones’ Special Porous Foam Reflects Heat And Can Be Used Close To Heat Sources.

The RF-120 Silicone Is A Highly Efficient Heat Insulation Material, Perfect For Managing Heat Effectively.

BISCO Silicones’ MS Silicone Performs Well Across A Wide Temperature Range, From -55°C To 200°C, Making It A Reliable Choice For Thermal Management.

These Silicone Materials From BISCO Silicones Are Versatile, Meeting The Needs Of Different Thermal Management Applications.

At Jiepu, We Offer Die-Cutting Services For BISCO Silicones And Other Materials, Helping You Find Custom Solutions For Your Thermal Management Needs.