Custom Your Die-Cutting Thermal Gap Pads

- Get the perfect Die-Cutting Thermal Gap Pads from Jiepu, a reliable Die-Cutting manufacturer from China

- IATF 16949:2016 Certification

- Flexible MOQ for Your Custom Thermal Gap Pads Die-Cutting Needs

- Over 20 years of Die Cutting experience

- Product Details

- Application Overview

- Material Insights

- The thermal gap pads offer excellent compatibility and heat transfer, meeting the thermal needs of electronics.

- The pads provide efficient heat connection for uneven surfaces, gaps, and rough textures.

- Thermal gap pads absorb shocks, making them ideal for pressure-sensitive applications.

- Thermal gap pads offer electrical insulation, protecting components from electrical currents.

- They are flame-resistant, meeting UL 94 V-0 standards for safe use.

Jiepu, with years of die-cutting experience, introduces Thermal Gap Pads, which are essential for improving heat transfer in electronic devices. Here are their key applications:

- Automotive Electronics: Thermal Gap Pads provide efficient heat transfer between heat sinks and electronic parts, especially in uneven or rough surfaces like in car infotainment systems.

- Computers and Gaming: They fill air gaps between high-performance components like CPUs and GPUs, improving heat flow for better performance.

- Data Communication: In servers and data centres, these pads help cool processors and storage devices, ensuring stable operation.

- Aerospace: Thermal Gap Pads handle extreme temperature changes in aerospace electronics and control systems.

- Handheld Devices: In smartphones and tablets, they transfer heat from processors and batteries to the outer shell or cooling system.

- Home Appliances: Used in devices like microwaves and washing machines, they help manage heat in power modules and control boards.

- Lighting: In LED lights, these pads help transfer heat to heat sinks, improving energy efficiency and extending lifespan.

- Medical Devices: In ultrasound and diagnostic equipment, they ensure stable heat management for reliable performance.

- Power and Industrial Automation: Thermal Gap Pads improve heat management in industrial control units and power equipment, reducing failure rates.

Jiepu, with years of die-cutting experience, introduces the different types of Thermal Gap Pads and their key features:

- Silicone-based Thermal Gap Pads: Made with silicone and thermal fillers like aluminium oxide, they are flexible and provide good heat transfer, making them ideal for uneven surfaces.

- Non-Silicone Thermal Gap Pads: These pads use other polymers instead of silicone, perfect for sensitive applications like optical devices where silicone could cause issues.

- High Thermal Conductivity Gap Pads: Made from materials like graphite or diamond, these pads have high heat conductivity, ideal for cooling high-power electronics like chips and LEDs.

- Vertical Graphite-Silicone Gap Pads: These combine graphite’s high heat conductivity with silicone’s flexibility, offering good performance at a lower cost.

- Compressible Thermal Gap Pads: These pads can compress to fit different surfaces, making them perfect for applications with varying assembly tolerances.

Custom Die-Cut Solutions with Thermal Gap Pads

At Jiepu, we specialise in providing custom die-cut solutions using Thermal Gap Pads, designed to meet the specific needs of industries such as automotive electronics and security. Our services include tailored designs, precise cutting techniques, and a wide range of materials to ensure the best performance and reliability. Whether for small or large-scale production, we offer flexible and efficient solutions to help enhance product quality, reduce costs, and accelerate time-to-market.

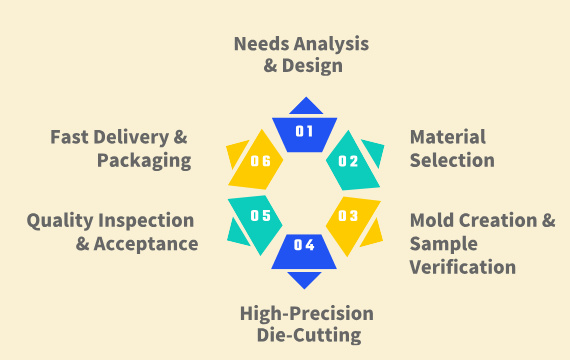

Precision Die-Cutting Process for Thermal Gap Pads

At Jiepu, we use precise die-cutting to shape Thermal Gap Pads accurately.

The process begins with material preparation, ensuring the pads—made from silicone and thermal fillers—are free of defects.

We then design a custom mould based on the pad’s thickness and shape, using flatbed or rotary cutting methods for clean results.

Additional steps, like punching holes or trimming, ensure complex shapes meet exact needs while preserving the pad’s flexibility and thermal performance.

Certified Die-Cutting Expertise with Thermal Gap Pads

We’re committed to excellence with certifications like ISO 9001, ISO 14001, and IATF 16949, ensuring precision, quality, and sustainability.

Our Thermal Gap Pads are advanced materials designed to improve heat transfer between electronic components and heat sinks. These pads are highly thermally conductive and electrically insulating, ensuring devices run efficiently and stay cool. Custom sizes and shapes are available to fit your needs, with a fast 48-hour sample delivery.

Thermal Gap Pads Sample Requests and Quotation Process

The Thermal Conductivity Of Thermal Gap Pads Varies Depending On The Material And Type Of Product.

For Standard Thermal Silicone Pads, The Thermal Conductivity Is Usually Around 1.0-3.0W/m·K.

High Thermal Conductivity Silicone Pads Have A Conductivity Range Of 1.5-3.0W/m·K.

Some Special Products, Like BERGQUIST® GAP PAD TGP 10000ULM, Can Reach 10.0W/m·K.

Other Variants Like THERM-A-GAP PAD 30 Offer 3.2W/m·K, While THERM-A-GAP PAD 80 Has 8.3W/m·K, And THERM-A-GAP PAD 70TP Has 7.0W/m·K.

In General, The Thermal Conductivity Of Thermal Gap Pads Ranges From 1W/m·K To Over 10W/m·K, Depending On The Product And Material Type.

At Jiepu, We Provide Die-Cutting Services To Customize Thermal Gap Pads To Meet Your Specific Needs.

The Temperature Range For Thermal Gap Pads Varies Depending On The Material Type.

For Standard Silicone Rubber Pads, They Can Be Used Continuously Between -60°C And +200°C, With Short Peaks Up To +250°C.

Solid Silicone Rubber Pads Have A Similar Range, From -60°C To +200°C, But Can Handle Short Spikes Up To +300°C.

Glass Silicone Rubber Pads Can Withstand -60°C To +300°C Continuously, With Peaks Up To +350°C.

Silicone Nitride Pads Offer An Even Broader Range, From -70°C To +350°C, With Peaks Reaching +400°C.

Some High-Temperature Pads Have A Working Range From -50°C To +200°C.

Most Thermal Gap Pads Generally Work Between -40°C And +200°C.

At Jiepu, We Provide Die-Cutting Services To Tailor Thermal Gap Pads To Your Specific Temperature And Application Requirements.

The Electrical Insulation Performance Of Thermal Gap Pads Can Be Summed Up In A Few Key Areas.

The Breakdown Voltage Is Typically Above 10kV/mm, Meaning The Material Can Withstand High Voltage Before Failing, Providing Strong Electrical Isolation.

The Surface Resistance Is Often Higher Than 1.0×10^12 Ω·cm, Indicating The Pad Has A High Resistance To Electric Current, Ensuring Electrical Safety.

The Dielectric Strength Is Usually Above 10kV/mm, So The Material Remains Insulated Even Under High Voltages.

Some Thermal Gap Pads Have A Volume Resistance As High As 10^13 Ω·m, Further Proving Their Excellent Insulating Properties.

These Pads Also Have Flame Retardant Properties, With UL-94 V-0 Rating, Meaning They Won’t Continue Burning When Exposed To Flames, Reducing The Risk Of Electrical Fires.

The Dielectric Constant Is Around 6.0, Which Affects How The Pad Reacts In An Electric Field. A Lower Dielectric Constant Helps Minimise Electrical Interference.

Overall, Thermal Gap Pads Provide Excellent Electrical Insulation, Making Them Ideal For Heat Management Applications That Require Electrical Isolation.

At Jiepu, We Offer Die-Cutting Services To Tailor Thermal Gap Pads To Your Specific Insulation Needs.

The Ability Of Thermal Gap Pads To Support Heavy Loads Depends On Their Material Properties And Design. Here Are Some Key Points To Consider.

Thermal Gap Pads Have Flexibility And Compressibility, Allowing Them To Fit Well Between Power Devices And Heat Sinks Or Enclosures, Which Helps With Efficient Heat Transfer.

Their Tear Strength Indicates How Well The Material Can Handle Stress And Repeated Disassembly, Typically Ranging From 0.4 To 0.6 kN/m. Stronger Options Should Be Chosen For Higher Loads.

The Hardness And Density Of The Pad Vary, With Shore Hardness Typically Ranging From 30 To 80. Pads With Lower Hardness Are Preferable To Minimise Pressure During Compression.

Tear Strength Measures The Maximum Force Required To Tear The Pad Along A Cut. This Reflects The Pad’s Durability And Ability To Withstand Stress Without Failing.

Compression Set Shows How Well A Pad Recovers After Being Compressed. Pads Made From Domestic Materials May Experience A Compression Set Of 40% To 65%, So They Are Not Recommended For Repeated Use.

If The Thermal Pad Is Thin (Under 1mm) Or Used In High-Pressure Areas, Adding Reinforcement Materials Like PI Film Or Silicone Fabric (With Glass Fibres) Can Enhance Its Strength.

In Conclusion, Whether A Thermal Gap Pad Can Support Heavy Loads Depends On The Specific Application And Product Specifications. In Some Cases, Reinforced Materials Are Needed To Improve Strength.

Jiepu Offers Die-Cutting Services, Tailoring Thermal Gap Pads To Meet Your Specific Requirements For Strength And Performance.

The Storage Conditions For Thermal Gap Pads Are Quite Important To Maintain Their Performance. Here Are Some Key Points:

Store Thermal Gap Pads In A Cool, Dry Place, Away From Heat. Ideally, The Temperature Should Be Around 30°C.

Keep Them Away From Moisture And Water, As High Humidity Can Affect Their Thermal Conductivity And Stability.

Avoid Direct Sunlight To Prevent UV Damage To The Material.

Ensure Good Ventilation In The Storage Area To Prevent Temperature And Humidity Fluctuations.

Once Opened, Thermal Gap Pads Should Be Used Quickly And Sealed To Keep Out Dust And Contaminants.

Avoid Mixing Different Brands Or Models, As This Could Affect Performance Or Cause Chemical Reactions.

Stack Them No Higher Than 7 Layers, And Keep The Total Height Below 1 Meter.

Under Proper Storage Conditions, The Shelf Life Is Usually 2 Years, But In Poor Conditions, It Drops To 6 Months.

At Jiepu, We Offer Die-Cutting Services To Help You Get The Right Thermal Gap Pads That Meet Your Needs.