Quality Die-Cutting Rubber Sheet Manufacturing

- Over 20 years of Die Cutting experience

- ISO9001 certified, any size, style, design, color can be customized to meet your needs

- Efficient Die-Cutting Rubber Sheet Solutions from China

- Applicable to various fields

- Product Details

- Application Overview

- Material Insights

- Rubber sheets are flexible and return to shape after stretching or compression.

- Rubber sheets resist friction and wear, making them ideal for heavy-use applications.

- Rubber sheets handle chemicals like acids and alkalis without damage.

- They block gas, liquid, and dust, perfect for sealing applications.

- Rubber sheets resist aging caused by natural elements or chemicals, lasting longer.

- Electrical Insulation: Some rubber sheets provide strong insulation for electrical and electronic uses.

Jiepu, with years of die-cutting experience, has provided services across various industries using Rubber Sheet materials. Here are its main applications:

- Industrial Applications: Rubber sheets are used for sealing, insulation, and vibration dampening in industries. Materials like EPDM are commonly used for automotive seals due to their weather resistance.

- Automotive and Motorsports: Rubber sheets are used in car bumpers, tyres, floor mats, and hoses, as they can withstand wear, extreme temperatures, and chemicals.

- Aerospace: Rubber sheets are essential in aircraft for floor coverings, seals, gaskets, and hoses, due to their ability to handle extreme temperatures and harsh chemicals.

- Marine: In the marine industry, rubber sheets are used for boat floors, decks, and fenders, as they resist water and harsh conditions.

- Construction: Rubber sheets are used for roof membranes, floor coverings, and joint seals. Their insulation properties make them ideal for waterproofing and soundproofing.

- Medical and Pharmaceutical: Due to their low allergenic properties and resistance to liquids, rubber sheets are used in surgical gloves, tubing, and masks.

- Sports and Fitness: Rubber sheets are used in sports facilities and playgrounds for shock absorption and non-slip surfaces.

Jiepu, with years of die-cutting experience, introduces the various types of rubber sheets and their unique characteristics:

- Natural Rubber Sheets: Known for excellent elasticity, flexibility, and wear resistance, these sheets are ideal for seals, gaskets, and flooring due to their strong mechanical properties.

- Synthetic Rubber Sheets: These include different types such as:

- EPDM: Great for outdoor use due to its weather and ozone resistance.

- Neoprene: Known for its oil, ozone, and heat resistance, suitable for automotive and industrial use.

- Silicone: Can handle extreme temperatures and is perfect for medical and food processing industries.

- Nitrile: Resistant to oil, fuel, and chemicals, making it ideal for the automotive and petroleum industries.

- Specialty Rubber Sheets:

- Viton: Offers excellent resistance to chemicals, heat, and oil, used in extreme industrial conditions.

- Butyl: Known for its gas barrier properties, ideal for applications requiring strong gas resistance.

Custom Die-Cut Solutions with Rubber Sheet

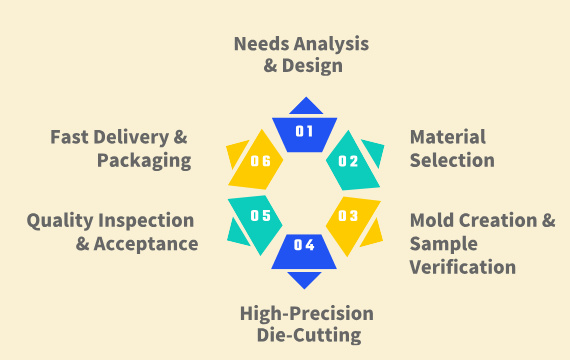

At Jiepu, we specialise in providing customised die-cut services using high-quality materials like Rubber Sheet. Whether you’re working in automotive electronics, security, or other industries, we deliver precision-cut solutions tailored to your specific needs. Our quick turnaround, diverse material options, and advanced cutting techniques ensure your products meet the highest standards, helping you save costs and speed up production.

Certified Excellence in Rubber Sheets Die-Cutting

We combine global certifications with expert die-cutting services.

Our ISO 9001 certification ensures consistent quality and customer satisfaction, while ISO 14001 reflects our focus on sustainability. For automotive clients, our IATF 16949 certification meets strict industry standards.

We provide high-performance Rubber Sheets known for durability and shock resistance, ideal for industrial and vehicle flooring. Custom shapes and sizes are available to fit your needs, with materials supplied in rolls for flexible production.

Rubber Sheet Die-Cutting Samples and Quotation Process

At Jiepu, we’ve streamlined the process for requesting Rubber Sheet samples and quotes. Here’s how it works:

- Quick Response: We provide quotes within 24 hours and samples within 72 hours to keep your project on track.

- Process Review: We evaluate your design for feasibility, production complexity, and any special requirements like positioning holes.

- Accurate Quotation: Pricing is based on material, process, and order size, with clear tiered options.

- Sample Preparation: Precise drawings and measurements are used to create accurate samples for final approval.

- Quality Check: Every sample undergoes detailed measurement, with a report provided to ensure high standards.

- Fast Shipping: Samples and documentation are securely packed and dispatched promptly, with tracking details shared within 24 hours.

- Supporting Documents: Relevant materials like SGS certificates, specifications, and inspection reports are included with your samples.

- Mould Design: We handle mould creation, from design to quality control, ensuring smooth production.

- Project Updates: Regular communication keeps you informed about progress and any design adjustments.

- Sample Approval and Production: Once samples are approved, production begins with consistent quality checks.

- Delivery and Follow-Up: We manage delivery and stay connected to ensure your satisfaction with the final product.

With a clear process and reliable timelines, we make it easy for you to receive accurate samples and quotes. Let Jiepu help simplify your Rubber Sheet die-cutting needs!

Rubber Sheets Perform Differently When Exposed To Chemicals Like Petrol, Benzene, And Toluene.

For Petrol, Materials Like Fluoroelastomer Offer Great Resistance To Oil And Solvents, While Nitrile Rubber (NBR) Works Well With Petrol And Fatty Oils.

Neoprene Rubber Is Also A Good Choice, With Better Resistance To Ozone, Heat, And Chemicals Than Natural Rubber.

When It Comes To Benzene, Some Rubber Types Can Swell Up To 500%, So Careful Selection Is Needed To Avoid Excessive Expansion.

For Toluene, Modified Rubber Stays Stable And Doesn’t Dissolve In Boiling Toluene Or Other Solvents.

Choosing The Right Rubber Sheet Depends On The Specific Chemical And The Performance You Need.

At Jiepu, We Offer Die-Cutting Services For Custom Rubber Solutions, Helping You Find The Best Fit For Your Applications.

The Dielectric Constant And Power Factor Of Rubber Sheets Vary Based On The Material.

For Natural Rubber, The Dielectric Constant At 1kHz Is Around 2.37.

Commercial Silicone Rubber Typically Has A Dielectric Constant Between 2.6 And 3.4 F/m, With Some Ranges Going From 1.8 To 5.2 F/m.

The Power Factor, Which Measures Conductivity, Is Usually Calculated Using Dielectric Loss. For Silicone Rubber, The Conductivity Is Between 7.7 × 10^-6 And 3.8 × 10^-5 S/m At 50-100 Hz.

The Dielectric Loss For Silicone Rubber Varies Between 1.0 × 10^-12 And 1.6 × 10^-5 S/m Depending On Frequency.

These Figures Give A General Idea Of The Dielectric Performance, But Keep In Mind That It Can Change Based On The Rubber Type, Fillers, And Other Factors.

At Jiepu, We Offer Die-Cutting Services To Help You Customise Rubber Sheets For Your Specific Needs.

The Price Differences Between Similar Rubber Sheet Products Can Be Explained By Several Factors:

Raw Material Costs: The price of natural and synthetic rubber can vary, which directly affects the cost of producing rubber sheets. For instance, fluctuations in the price of natural rubber can cause significant price changes.

Manufacturing Process: Different production methods can impact the performance and cost of rubber sheets. Advanced processes might improve performance but also increase costs, which can raise the price.

Market Demand: The demand for rubber sheets, especially durable ones, can push prices up. As industries like mining grow, so does the demand for high-quality rubber sheets.

Brand Influence: Well-known brands often offer better quality and customer service, which can justify a higher price.

Environmental Policies: Stricter environmental regulations may lead to higher production costs, which can affect the final price.

International Trade Policies: Changes in trade policies or tariffs can impact the cost of rubber sheet imports and exports, influencing prices.

Technological Advancements: As synthetic rubber technology improves and natural rubber becomes more sustainably sourced, costs can decrease, but performance might improve, affecting prices.

Market Competition: Increased competition pushes companies to improve their products and pricing strategies, which can affect rubber sheet prices.

Supply Chain Management: Global supply chain fluctuations can also impact costs, leading companies to optimise sourcing to reduce risks.

Product Differences: Variations in materials, production techniques, and quality control standards can lead to price differences among rubber sheets from different manufacturers.

At Jiepu, we understand these factors well and offer die-cutting services that cater to your specific material needs, ensuring both quality and cost-effectiveness.

Rubber Sheets Have Two Key Electrical Properties: Volume Resistivity And Breakdown Voltage.

Volume Resistivity Is A Measure Of The Material’s Insulating Ability. Rubber Sheets Generally Have Very High Volume Resistivity, Usually Over 10^8 Ω·cm. This Means They Are Excellent Insulators.

Breakdown Voltage Refers To The Maximum Voltage A Rubber Sheet Can Withstand Before It Breaks Down. For Example, A 4mm Thick Sheet Can Withstand A Minimum Of 15kV, While A 12mm Thick Sheet Can Withstand Up To 45kV.

These Properties Show That Rubber Sheets Are Reliable Insulating Materials, Providing Effective Protection Against Electrical Conductivity. Jiepu Offers Die-Cutting Services For Rubber Sheets, Customising Them To Your Needs.

The Flame Resistance of Rubber Sheets Depends on the Material and Formulation Used.

Different types of rubber have varying levels of flame resistance. For example, Chloroprene rubber (CR) contains chlorine, making it self-extinguishing when exposed to fire.

Adding flame retardants is another way to improve rubber’s flame resistance. Common flame retardants include organic halogens like chlorinated paraffins.

The oxygen index is a key measure of a material’s flammability. If the oxygen index is below 22, the material is highly flammable. Between 22 and 27, it’s considered flame-resistant. Above 27, the material is highly flame-retardant.

Rubber sheets are also classified according to their flame resistance under the UL94 standard. This includes grades like HB, V-2, V-1, and V-0, depending on how quickly they burn and whether they self-extinguish.

Some rubbers, like fluoroelastomers, can burn when exposed to flames but will automatically extinguish once the flame is removed, making them self-extinguishing.

To enhance flame resistance, rubber can be treated with additives or formulated with materials that meet specific national standards for fire resistance.

At Jiepu, we offer die-cutting services and provide rubber sheets with enhanced flame resistance tailored to your needs.