High Quality Die-Cutting Felt

- Get the perfect Die-Cutting Felt from Jiepu, a reliable Die-Cutting Felt manufacturer from China

- Customize various sizes For Felt

- Low MOQ From 500pcs to Support Your Business

- ISO9001 & ISO14001 Certification

- Product Details

- Application Overview

- Material Insights

- Die-cutting felt allows you to create unique shapes and patterns quickly and easily.

- It saves time, especially when making many identical pieces for crafts or decorations.

- Die-cut machines cut felt with perfect edges, ensuring consistent and professional-quality results every time.

- These machines can handle multiple felt layers at once, improving efficiency for large projects.

- Felt is durable, doesn’t fray after cutting, and is eco-friendly, making it a great material choice.

Jiepu has provided die-cutting services for industries such as packaging, medical, and automotive, using felt materials to create precise components.

Packaging and Printing:

Used for boxes, labels, and packaging. Die-cutting creates custom shapes and curves, making the packaging more attractive.

Digital Products:

Used for smart watch straps, screen protectors, and circuit boards. Die-cutting ensures precise components for high-tech gadgets.

LCD and LED Displays:

Used for optical films, light guides, and adhesive pads. Die-cutting provides the precision needed for display technology.

Office and Stationery Products:

Used for paper, sticky notes, and invoices. Die-cutting helps produce custom shapes quickly and in bulk.

Medical Devices:

Used for bandages, masks, and packaging. Die-cutting ensures consistent and safe production for medical products.

Transportation:

Used for dashboard parts, seals, and shock pads in vehicles. Die-cutting improves comfort and performance in transportation.

New Energy Sector:

Used for battery and solar components. Die-cutting meets the precise requirements of energy products.

With Jiepu’s extensive die-cutting expertise, we’re here to explain the key features of die-cut felt in a simple way.

Basic Composition:

Felt is made from natural wool or synthetic fibres like polyester or acrylic. These fibres are compressed and bonded into a non-woven structure, giving felt its elasticity and ability to hold its shape.

Production Process:

Felt is made by collecting, cleaning, and carding fibres, followed by layering, applying heat and moisture, and compressing them with rollers. This process determines its density, thickness, and smoothness.

Physical Properties:

Felt is elastic, making it ideal for shock absorption, sealing, and padding. Its compact structure makes it great for insulation and filtration, while its bonding strength ensures durability during use.

Die-Cutting Process:

Die-cutting precisely shapes felt into complex designs that are hard to achieve with scissors. Using thin metal dies, machines cut felt quickly and consistently, perfect for large-scale production.

Versatility:

Felt is highly versatile, used in decorations, crafts, clothing, and home goods. Die-cutting enhances its creative potential by allowing custom shapes and patterns.

Custom Die-Cutting Felt Solutions

At JIEPU, we specialise in providing tailored die-cutting services for Die-Cutting Felt, ensuring precise solutions for industries like automotive electronics and security. With a wide range of materials and advanced cutting technology, we offer custom designs that fit your specific needs. Our quick delivery and high-quality production help you reduce costs, enhance product quality, and speed up time-to-market. Contact us for reliable and flexible die-cutting solutions.

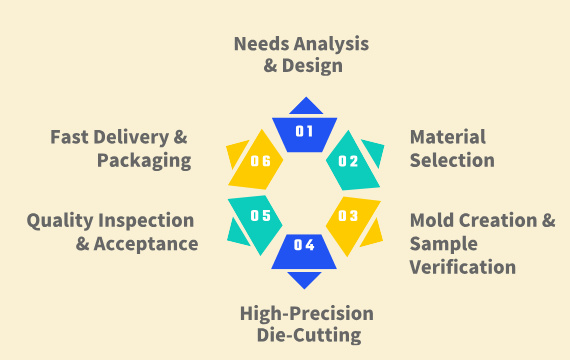

Precision Die-Cutting Process for Felt Materials

Based on Jiepu’s extensive experience, the die-cutting process for felt materials ensures high-quality results for products like soundproofing panels or seat cushions. Depending on the application, natural wool felt or synthetic fibre felt is selected for its thickness, density, and properties like sound absorption or elasticity. Flatbed or rotary cutting methods are commonly used for precise and efficient production.

Top-Quality Die-Cutting for Felt Materials

Jiepu delivers precise Felt Material die-cutting backed by certifications like ISO 9001, ensuring consistent quality from raw materials to final products. With ISO 14001, Jiepu uses eco-friendly processes to reduce waste and energy use. For automotive uses like seat pads and soundproofing, IATF 16949 guarantees high standards of reliability and performance.

Simple Guide to Sample Requests and Quotation Process

At Jiepu, with over 20 years of experience in die-cutting, we aim to make the process of requesting samples and receiving quotes simple and efficient. Here’s a clear and easy-to-follow guide for our potential customers.

Sample Request Process

- Submit Your Sample Requirements

Share detailed information about your needs, such as the product’s function, purpose, and expected performance. Include a complete design drawing (e.g., 2D files) that specifies materials, dimensions, and any special requirements. - Feasibility Review

We evaluate your design to ensure the sample can be produced and mass-manufactured smoothly. We check material availability and recommend commonly used materials to avoid procurement challenges. - Sample Production

Once everything is confirmed, we start creating your sample. Our team ensures it meets the required quality standards, and samples are typically ready within three days. - Delivery and Feedback

After quality checks, we ship the sample to you and provide tracking details within 24 hours. Once received, you can review and share feedback.

Quotation Process

- Cost Calculation

We calculate costs based on material, moulds, labour, and processing. For example, material cost is determined by the size of the product and unit price, while mould cost is spread across its expected lifespan. - Quote Creation

Depending on order size and complexity, we provide tiered pricing (e.g., 0–30k, 30–50k). We consider factors like processing methods and relationships with customers to ensure a fair price. - Quote Communication

You’ll receive the quote within 24 hours. If adjustments are needed, we’ll work with you until the pricing meets your expectations. - Order Confirmation

Once the quote is approved, we move forward with production based on the agreed terms, delivery schedule, and quality requirements.

Why Choose Jiepu?

Our streamlined sample and quotation processes ensure accuracy, transparency, and efficiency, helping you bring your ideas to life with ease. Ready to get started? Contact us today!

When Using Die-Cutting Felt, There Are Some Key Points To Keep In Mind.

First, keep the felt clean by regularly removing dust and fibres. You can use a soft brush or compressed air for cleaning.

It’s important to avoid contact with oils or harsh chemicals, as these can affect the material’s performance and bonding ability.

Store the felt in a dry place to prevent moisture buildup, which can lead to mould or deterioration. Make sure to keep it out of direct sunlight, as prolonged exposure can cause ageing and reduce its quality.

Always store the felt flat to avoid creases or deformation. This will help it maintain its shape for longer.

Make sure not to expose the felt to extreme temperatures, as this can cause damage. Avoid stretching or compressing the felt excessively during use to prevent deformation.

For installation, make sure the felt is correctly aligned with the die or other parts, applying even pressure during the cutting process to ensure consistent results.

Regularly check the felt for signs of wear and replace any parts that show damage. For adhesive applications, make sure the bonding is still effective.

Be careful not to let sharp objects damage the felt, and avoid placing heavy items on it that could cause deformation.

By taking these steps, you’ll help ensure the felt lasts longer and performs well, improving your production efficiency and product quality. At Jiepu, we offer die-cutting services and help clients ensure that their materials are properly maintained.

If You Notice Ragged Edges On Die-Cutting Felt, Here’s What To Do:

First, consider improving the cutting process.

Lowering the cutting speed can help ensure the blade completely cuts through the material, reducing ragged edges.

Adjusting the blade height and angle to match the felt can also make a difference.

Increasing the die-cutting pressure can ensure a clean cut, preventing edges from fraying.

Choosing the right tools is also key.

Use sharp blades that are suited for cutting felt, and replace worn-out tools regularly.

A tool with a smaller radius can also reduce the appearance of ragged edges.

Control your working environment.

Keep the temperature and humidity levels in the production area stable to prevent any issues that could affect the cutting quality.

If ragged edges still appear, consider post-processing.

You can manually smooth the edges using sanding or polishing techniques.

Alternatively, use dedicated edge-trimming tools for a more precise finish.

Make sure to choose high-quality felt to begin with and regularly maintain the cutting equipment.

At Jiepu, we provide die-cutting services that ensure top-quality products with minimal defects.

By following these steps, you can reduce ragged edges and improve the overall quality and appearance of your die-cut felt products.

Die-Cutting Felt Has A Wide Range Of Applications In The Automotive Industry.

- It Is Used To Solve Buzz, Squeak, And Rattle (BSR) Issues.

- Die-cut Felt Products Help Reduce Noise And Vibration Between Metal And Plastic Parts.

- They Also Act As Seals And Cushions For Various Parts Like Seats And Dashboards.

- Die-Cutting Felt Is A Good Choice For Filtration In Air Systems.

- It Works Well As An Oil Absorbent In Lubrication Systems.

- Additionally, It Helps Improve The Appearance Of Car Interiors.

- Die-Cutting Felt Also Offers Protection For Internal Parts And Ensures The Safety Of Airbags.

Jiepu Provides High-Quality Die-Cutting Services, Ensuring All Applications Are Met With Precision And Reliability.

Die-Cutting Felt Has Many Uses In Home Products. Here Are Some Common Applications:

For Decoration, Die-Cutting Felt Can Be Used To Make Wall Hangings In Various Shapes, Such As Flowers And Animals. It Adds A Warm And Unique Atmosphere To The Room.

For Curtains And Window Decorations, Felt Works Well To Reduce Noise And Maintain Room Temperature. It’s A Soft Material With Good Sound Absorption.

Furniture Upholstery, Such As Sofas And Bed Headboards, Can Be Made With Felt To Add Colour And Provide Extra Comfort.

In Protection And Cushioning, Felt Can Be Placed Under Furniture Legs To Protect Floors From Scratches And Reduce Noise When Moving Furniture.

Placing Felt On Desks Or Tables Helps Prevent Scratches And Can Also Keep Items From Sliding Around.

Felt Can Also Be Used To Create Wall Guards, Protecting Walls From Damage Caused By Furniture Collisions.

In Practical Uses, Felt Rugs And Mats Provide Comfort While Also Insulating Against Cold Floors. They Can Also Reduce Vibration And Keep The Floor Safe.

Felt’s Soundproofing Qualities Make It Ideal For Noise Reduction, Whether Used On Walls, Doors, Or Windows, Ensuring A Quieter Home.

These Versatile Applications Show How Die-Cutting Felt Can Add Both Functionality And Aesthetic Value To Your Home. Jiepu, Known For Our Die-Cutting Services, Can Provide High-Quality Felt Products For These Purposes.

When Die-Cutting Felt, Ensuring Accurate Dimensions is Crucial. We Use Some Ways to Achieve It:

Using High-Precision Equipment

A CNC Cutting Machine Can Ensure Accurate Cuts. It Automates Cutting Based on Set Dimensions, Reducing Human Error.

Sharp, High-Precision Tools Help Achieve Clean Edges, Preventing Rough Edges and Size Variations.

Optimising The Process

Before Cutting, Input and Verify The Desired Dimensions to Ensure Accuracy.

Run a Test Before Full Production To Check If The Product Matches The Desired Size. Adjust Equipment If Necessary.

Controlling Environmental Conditions

Maintain Stable Temperature To Prevent Material Expansion or Shrinking, Affecting Size.

Keep Humidity Levels in Check To Avoid Overly Dry or Wet Felt, Which Can Impact the Cut.

Material Preparation

Ensure The Felt is Flat Without Wrinkles to Prevent Size Inaccuracies.

Control The Tension of The Felt During Cutting to Avoid Deformation.

Precise Positioning and Clamping

Use High-Precision Positioning Systems To Ensure Felt Stays in Place During Cutting.

Use Clamps to Hold The Material Steady, Preventing Movement or Shifting.

Regular Equipment Maintenance and Calibration

Regularly Maintain the Cutting Equipment To Keep It in Good Working Condition.

Ensure The Equipment Is Properly Calibrated to Meet Size Accuracy Standards.

At Jiepu, We Ensure Accurate Die-Cutting Services By Implementing These Best Practices To Achieve High-Quality Results.