Your Specialist For Die-Cutting Urethane Rubber

- Leading Die-Cutting Manufacturer, Producing Urethane Rubber for Your Industry

- ISO9001 certified, any size, style, design, color can be customized to meet your needs

- Quick Samples from China

- Low MOQ

- Product Details

- Application Overview

- Material Insights

- Urethane rubber, also called polyurethane elastomer, has excellent durability and high resistance to wear.

- Its abrasion resistance is 3-10 times better than natural rubber in most applications.

- Urethane rubber has high strength and flexibility, even in hardness levels between Shore A60 and A70.

- It absorbs 10-20% of vibration energy, making it perfect for shock-absorbing parts and equipment.

- Urethane rubber resists oils, chemicals, and harsh conditions, widely used in automotive and industrial fields.

Custom Die-Cutting Services for Urethane Rubber

JIEPU offers bespoke die-cutting services for Urethane Rubber, designed to meet the specific needs of industries such as automotive electronics and security. Our precise cutting ensures a perfect fit for your products, whether for small or large scale production. With a wide range of material choices and quick delivery times, we help you improve product quality, reduce costs, and accelerate your time-to-market. Let us support your business with our tailored die-cutting solutions.

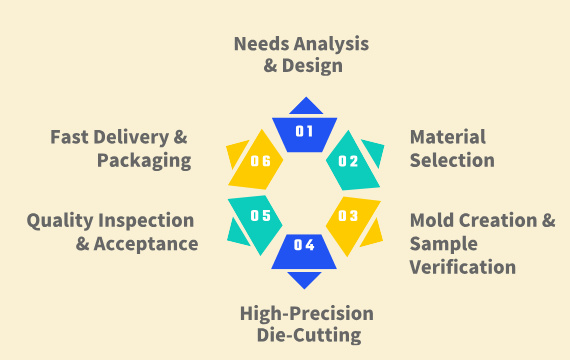

Efficient Die-Cutting Process for Urethane Rubber

With Jiepu’s expertise, the die-cutting process for urethane rubber focuses on precision and durability. Materials like castable, compoundable, or thermoplastic polyurethane are chosen based on hardness and resistance needs. Techniques such as flatbed cutting for thin sheets or rotary cutting for thicker materials deliver high-quality, customised solutions.

Reliable Die-Cutting for Urethane Rubber

Jiepu ensures top-quality Urethane Rubber die-cutting with certifications like ISO 9001, guaranteeing every step meets strict standards. Using eco-friendly methods under ISO 14001, Jiepu minimises waste and energy use. With IATF 16949, their products meet automotive demands, offering durability and precision for applications like seat pads and shock absorbers.

- Keep Temperature Stable. Avoid extreme heat or cold to prevent material damage.

- Protect From Chemicals. Keep away from strong acids, bases, or corrosive substances.

- Avoid Overstretching. Do not over-pull or compress to prevent fatigue or deformation.

- Shield From Sunlight. Long exposure to UV rays can weaken the rubber.

- Clean Regularly. Use mild cleaners and soft cloths to maintain surface quality.

- Prevent Scratches. Keep away from sharp objects to avoid damage.

- Store Properly. Use a dry, ventilated space to avoid dampness or stacking issues.

The lifespan of polyurethane rubber depends on its use and environment, typically lasting several years with proper care.

High temperatures and long exposure to UV light can accelerate ageing, while strong chemicals may cause damage. Heavy loads or frequent stress can reduce durability, but regular cleaning and applying lubricants help minimise wear.

For best results, store the material in a cool, dry place, away from sunlight and moisture. At Jiepu, we offer professional die-cutting services to ensure precision and maximise the performance of polyurethane materials.

Polyurethane rubber plays a key role in the automotive industry, thanks to its durability and flexibility. At Jiepu, our die-cutting services help create precise and efficient polyurethane components for these applications.

- Bumpers use polyurethane to absorb impact during collisions.

- Body panels and grills benefit from its toughness and weather resistance.

- Car seats and headrests use polyurethane foam for comfort and support.

- Shock pads and spring insulators reduce vibrations and improve suspension.

- Airbag coatings ensure strength and flexibility for safety during impact.

- Seals and gaskets provide long-lasting sealing and resistance to ageing.

This material enhances vehicle performance, safety, and comfort across many parts.

Polyurethane Rubber Is Widely Used In The Electronics Industry, Offering Several Key Benefits.

It Is Commonly Used For Encapsulating Electronic Components Like Integrated Circuits And Sensors.

The Rubber Provides Excellent Heat Transfer To Prevent Overheating And Keeps Dust, Moisture, And Harmful Elements Out.

Its High Elasticity Also Helps Support And Protect Electronic Parts During Operation And Transport.

In Wires And Cables, Polyurethane Rubber Is Used As An Insulation Layer To Prevent Short Circuits.

It Also Acts As A Protective Coating, Offering Resistance To Wear And Chemicals, While Extending The Life Of Cables.

Polyurethane Rubber Is Essential In The Assembly Of Electronic Devices, Serving As An Adhesive To Bond Parts Together.

It Helps In Fixing And Supporting Components To Ensure Stability And Proper Placement During Assembly.

In Device Housings, The Rubber Protects Against Impact And Wear, Shielding Sensitive Components Inside.

It Is Also Used For Vibration Damping, Absorbing Shocks And Reducing Wear Over Time.

Other Applications Include LED Lighting, Where Polyurethane Rubber Helps With Heat Dissipation, And In Medical Equipment For Sealing Sensitive Parts.

At Jiepu, We Specialise In Die-Cutting Services, Ensuring The Highest Quality And Precision For All Your Polyurethane Rubber Needs.