High Quality Die-Cutting Silicone Rubber

- Custom Die-Cutting Silicone Rubber to Power Your Projects

- Flexible MOQ for Your Custom Die-Cutting Silicone Rubber Needs

- We will design a custom, cost-effective solution for your business

- IATF 16949:2016 Certification

- Product Details

- Application Overview

- Material Insights

- Silicone rubber is a flexible material that stays stable in extreme temperatures from -60°C to 250°C.

- It doesn’t soften in heat or crack in cold, making it highly durable.

- Silicone rubber is an excellent insulator, ideal for electrical components in humid or high-heat environments.

- It resists chemicals like acids and solvents, ensuring reliability in harsh industrial applications.

- Silicone rubber is safe, non-toxic, and eco-friendly, widely used in medical and outdoor products.

Jiepu has provided die-cutting services for industries using silicone rubber, including electronics, automotive, and medical sectors. Silicone rubber is highly versatile due to its durability and resistance to extreme conditions.

Electronics and Electricals:

Used in cable jackets, seals, and insulators. It resists heat, moisture, and electricity, ensuring devices work safely outdoors or in tough environments.

Automotive Industry:

Used in engine seals, hoses, and O-rings. Its heat and oil resistance makes it perfect for high-temperature engine parts.

Medical and Hygiene:

Used in catheters, baby bottle teats, and medical seals. It’s safe for the body, non-toxic, and works well under sterilisation conditions.

Construction and Home Use:

Used in window seals, waterproofing, and roof joints. It adapts to weather changes and keeps buildings watertight and flexible.

Aerospace:

Used in insulation, heat shields, and seals. It performs reliably in extreme heat and cold, ideal for aerospace equipment.

Food Industry:

Used in baking moulds, food containers, and gaskets. It’s safe for food, resists chemicals, and can handle high temperatures.

With years of die-cutting expertise, Jiepu is here to introduce the key features of silicone rubber in a way anyone can understand.

Molecular Structure:

Silicone rubber is made up of silicon and oxygen atoms (-Si-O-Si-), creating very strong bonds. These bonds give it excellent heat resistance, making it more durable than regular rubber.

Vulcanisation Process:

Silicone rubber can cure (harden) at high or room temperatures. This process creates a strong 3D network, making the material stable and strong in different conditions.

Heat Resistance:

Thanks to its flexible molecular chains, silicone rubber can handle high temperatures without cracking or losing its shape.

Electrical Insulation:

It’s a great insulator, even when burned, as it forms silica, which remains non-conductive. It can also resist electrical sparks and arcs.

Surface Properties and Safety:

Silicone rubber doesn’t absorb much water and resists mould growth. It’s non-toxic, odourless, and safe for humans, making it suitable for medical and food-grade uses.

Gas Permeability:

It allows gases like oxygen and nitrogen to pass through more easily than natural rubber, with a higher preference for oxygen.

Chemical Resistance:

Silicone rubber resists most chemicals, including acids, bases, and solvents, making it ideal for use in harsh industrial environments.

Oil, Radiation, and Flame Resistance:

It remains stable in oils, fuels, and solvents at both high and low temperatures. It also resists radiation and burns slowly.

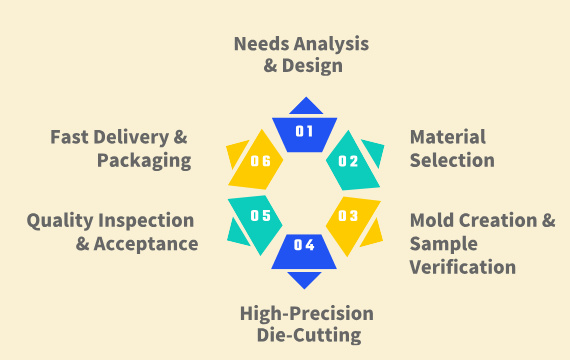

Custom Die-Cutting Services for Silicone Rubber

At JIEPU, we offer tailored die-cutting solutions for Silicone Rubber, ideal for industries like automotive electronics and security. Our high-precision cutting ensures that each piece fits your exact needs, whether for small or large production runs. With a variety of materials and rapid delivery, we help you optimise production, reduce costs, and speed up time-to-market. Let us enhance your product quality with our custom die-cutting expertise.

Precise Die-Cutting Process for Silicone Rubber

Based on Jiepu’s extensive experience, the die-cutting process for silicone rubber involves selecting the right material, such as liquid silicone rubber (LSR) or high-consistency rubber (HCR), depending on its required flexibility and temperature resistance. Techniques like flatbed cutting for thin pieces and rotary cutting for larger shapes ensure precise results for various applications.

High-Quality Die-Cutting for Silicone Rubber Materials

Jiepu delivers exceptional Silicone Rubber die-cutting services, backed by ISO 9001 certification. This ensures every stage, from raw material selection to final inspection, meets strict quality standards. With ISO 14001, Jiepu uses eco-friendly processes, reducing waste and pollution. For automotive needs, IATF 16949 guarantees reliable and high-performance results.

Discover New Die Cutting Materials

Easy Steps for Silicone Rubber Sample Requests and Quoting

At Jiepu, with over 20 years of expertise in die-cutting, we make requesting Silicone Rubber samples and getting a quote simple. Here’s a clear guide to help you get started.

Sample Request Process

- Share Your Needs

Tell us the details, like size, shape, thickness, material type (e.g., liquid silicone rubber or high-consistency rubber), colour, and surface treatment. The more details, the better we can match your needs. - Discuss the Application

Let us know how and where you’ll use the product. This helps us tailor the sample to meet your specific requirements. - Provide Drawings or Samples

Share a design drawing or a physical sample so we can create an accurate prototype. - Sample Creation

We’ll make your sample with strict quality checks, ensuring precision in size, shape, and performance. - Delivery and Feedback

Once the sample is ready, we’ll ship it and send you the tracking info. Test the sample and let us know if adjustments are needed. - Documentation Provided

We’ll include material certificates, testing reports, and quality details so you can fully understand your sample.

Quotation Process

- Cost Calculation

We calculate costs based on material, moulds, production, labour, and wastage. This ensures transparency in pricing. - Flexible Pricing

Our quotes offer tiered pricing depending on order size (e.g., 0–30k, 30–50k). Sample fees for new customers can often be credited toward bulk orders. - Review the Quote

We’ll send you a detailed quote with product specs, unit costs, total price, and delivery timelines. Let us know if anything needs adjusting. - Confirm the Order

Once you’re happy with the quote, we’ll finalise the agreement and proceed with production based on your requirements.

Why Work With Jiepu?

We combine technical expertise with customer-friendly service, ensuring smooth communication, top-quality samples, and accurate quotes. Reach out today to get started!

Silicone Rubber typically has a temperature range from -60°C to 250°C.

In special formulas, it can even handle up to 300°C.

This wide temperature tolerance makes it perfect for many industrial applications.

Silicone Rubber Hardness Is Measured Using Shore A Scale, Ranging From 10° To 90°.

Here Are Some Common Hardness Levels And Their Features:

- 10° Shore A: Very Soft, Like Sponge, Used For High-Flexibility Applications.

- 20° Shore A: Soft And Comfortable, Like Rubber Bands, Suitable For Personal Accessories.

- 30-50° Shore A: Soft With Good Elasticity, Ideal For Phone Cases, Baby Teethers.

- 50-60° Shore A: Balances Softness And Compression Resistance, Used For Headphone Covers, Game Controllers.

- 70-80° Shore A: Hard And Durable, Suitable For Automotive Parts, Tool Handles.

![]()

Silicone Rubber Typically Lasts Between 5 To 20 Years.

Its lifespan depends on the environment and usage.

For example, in automotive applications, it lasts about 10 to 15 years.

In medical equipment, it can range from 5 to 20 years.

For consumer products like kitchen tools, it’s usually 5 to 10 years.

In industrial settings, silicone rubber can last between 10 to 20 years.

Temperature, chemical exposure, and mechanical stress affect its lifespan.

Jiepu, offering silicone rubber die-cutting services, ensures high-quality results for silicone rubber parts.

If the stickiness of silicone rubber decreases during use, try these methods:

First, clean the surface of the silicone rubber by gently wiping it with a clean cloth or soft brush. This will remove dust, oil, and other impurities.

If cleaning doesn’t work, you can use an anti-stick agent. A mixture of liquid Teflon, white spirits, and a curing agent can be sprayed on the surface to create a protective layer and reduce stickiness.

Another approach is adjusting the silicone rubber’s formula. During production, you can increase the ratio of base material and silicone oil, or reduce fillers like white carbon black.

You can also consider surface treatment methods, like sandblasting, which will give the surface a matte finish and reduce its stickiness.

Finally, make sure to store and use the silicone rubber under the right conditions. Avoid high temperatures, UV exposure, and chemical corrosion to maintain its performance.

If you’re looking for precision die-cutting services for silicone rubber or any related materials, Jiepu can help ensure the best results.