Your Specialist For Die-Cutting Hook and Loop

- Affordable Die-Cutting Hook and Loop for All Industries

- 3-day rapid production of samples

- Your One-Stop Shop for Custom Die-Cutting Hook and Loop

- ISO9001 & ISO14001 Certification

- Product Details

- Application Overview

- Material Insights

- Hook and Loop, also called Velcro, is made of hooks on one side and loops on the other.

- It is easy to use—just press to stick and pull apart to release.

- Hook and Loop can be reused many times without losing its sticking power, making it practical.

- It works on fabrics, plastics, metals, and more, suitable for clothing, bags, and electronics.

- Hook and Loop is customizable in size, color, and shape, meeting different needs across various industries.

Jiepu has supplied die-cutting services for industries using Hook and Loop materials, such as fashion, automotive, and defence. This versatile material sticks and separates easily, making it perfect for quick fixes.

Clothing and Fashion:

Used in kids’ clothes, sports straps, and backpack adjusters. It’s simple to use, especially for children and the elderly.

Medical Devices:

Used in bandages, prosthetic straps, and medical kits. It’s adjustable and reusable, perfect for frequent changes.

Automotive Industry:

Used for fixing car seats, interior trims, and dashboard decor. It holds securely but removes easily for repairs.

Electronics:

Used to manage cables, fix battery covers, and secure device panels. It’s reliable and reusable, keeping devices tidy.

Home Products:

Used in carpets, curtains, and furniture trims. It’s easy to install and remove, ideal for adjustable household items.

Industrial Applications:

Used for fixing toolboxes, equipment panels, and maintenance covers. It works well in tough environments and lasts long.

Aerospace and Defence:

Used for securing spacecraft equipment and military gear. It’s reliable in extreme conditions and allows quick setup.

With years of expertise in die-cutting, Jiepu is here to explain the unique features of Hook and Loop fasteners in simple terms.

Structure Design:

Hook and Loop has two sides: a hook side with tiny nylon hooks and a loop side made of soft fibres. When pressed together, the hooks catch the loops, creating a secure bond.

Material Choice:

It is usually made of durable nylon, which resists wear and works well in different environments. The hook side is stiff and strong, while the loop side is soft and dense.

Manufacturing Process:

The process includes weaving nylon into strips, shaping them with heat, adding adhesive for durability, and cutting hooks into the desired form.

Locking Mechanism:

The connection is based on a simple interlocking system—hooks grab onto loops, allowing easy and reusable fastening without zippers or buckles.

Versatility:

Hook and Loop works in many fields, from clothing to industrial use. Its design handles different weights and conditions, making it a reliable choice for quick fastening.

Custom Die-Cutting for Hook and Loop Solutions

At JIEPU, we provide precision die-cutting services for hook and loop materials, ensuring perfect fits for applications in electronics, automotive, and more. With custom designs and advanced equipment, we create high-quality, durable components tailored to your needs. Whether for small or large orders, our solutions help you improve efficiency and meet tight timelines.

Efficient Die-Cutting Process for Hook and Loop Materials

With Jiepu’s expertise, we use precise die-cutting techniques to shape Hook and Loop materials like nylon and polyester. Common methods include flatbed cutting for thinner designs and rotary cutting for larger or continuous patterns. These processes ensure the material’s flexibility and performance for customised fastening solutions.

Certified Die-Cutting Process for Hook and Loop Materials

Jiepu ensures top-notch quality in die-cutting Hook and Loop materials with its ISO 9001 certification. This guarantees every step, from raw material inspection to final product checks, meets strict quality standards. With ISO 14001, Jiepu also follows eco-friendly practices, minimising waste and pollution during production, ensuring sustainable manufacturing.

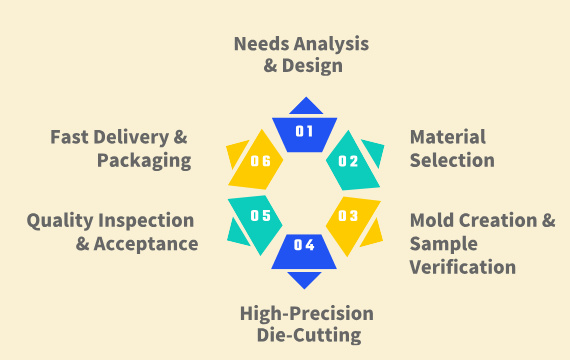

How to Request Hook and Loop Samples and Get a Quote

At Jiepu, we specialise in simplifying the die-cutting process for Hook and Loop materials. With over 20 years of experience, we ensure clear communication, high-quality samples, and efficient quoting. Here’s an easy-to-follow guide for new customers.

Sample Request Process

- Share Your Requirements

Tell us what you need, including the size, shape, thickness, material type (hook and loop), colour, and any surface treatments. Let us know where and how the product will be used. - Provide Your Design

Send us a drawing or a sample of your product. This helps us create a prototype that matches your expectations. - Sample Production

We’ll make the sample, focusing on accuracy and consistent quality. Our team ensures all technical requirements are met. - Sample Delivery

Once the sample is ready, we’ll ship it and email you with tracking details. You can test the sample and provide feedback for any adjustments. - Supporting Documents

We include all relevant documentation, such as material certificates, testing reports, and production details, so you have a full understanding of the sample’s quality.

Quote Process

- Cost Breakdown

We calculate costs based on materials, moulds, labour, and production, ensuring complete transparency. - Tiered Pricing

Our quotes offer flexible pricing based on quantity ranges (e.g., 0–30k, 30–50k). For new customers, sample fees may apply but can be credited toward your first order. - Review and Adjust

We’ll send a detailed quote that includes specifications, unit prices, quantities, and delivery timelines. Let us know if you need any adjustments. - Order Confirmation

Once you approve, we’ll formalise the agreement with a clear contract covering all technical and commercial details.

Why Choose Jiepu?

We combine precision, efficiency, and customer-first service to simplify your Hook and Loop die-cutting needs. Contact us today to get started!

At Jiepu, we prioritise precise material testing to ensure reliable performance. The adhesion strength of hook and loop fasteners is typically measured through peel strength, shear strength, and tensile strength tests. These methods evaluate how well the fastener holds under various forces.

Peel Strength Test

Peel strength measures the force needed to separate the fastener at a specific angle, often 90° or 180°.

- Stick the hook and loop surfaces together, ensuring no air bubbles.

- Attach them to a testing machine with one surface connected to the top clamp and the other to the bottom.

- Set the pulling speed (e.g., 300mm/min).

- Record the force needed to peel them apart.

Higher peel strength means stronger adhesion. Results are expressed in Newton (N) or pound-force (lb).

Shear Strength Test

Shear strength tests the force required to slide the hook and loop apart in the plane of the adhesive.

- Stick the hook and loop together with aligned surfaces.

- Secure the fastener in the testing device, ensuring the force is parallel to the bonded area.

- Set a slower speed (e.g., 1mm/min) and apply force until they separate.

The stronger the shear strength, the better the hold under parallel stress.

Tensile Strength Test

Tensile strength measures the force needed to pull the hook and loop apart directly, perpendicular to the adhesive area.

- Stick the two surfaces together firmly.

- Mount them vertically in the machine, with the bonded area positioned flat.

- Apply force at 300mm/min until separation occurs.

The test shows how well the fastener holds under a pulling force.

Important Notes

- Always clean the surfaces of the fastener to avoid interference from dust or oil.

- Ensure consistent bonded areas to get comparable results.

- Perform tests in standard lab conditions (e.g., 23°C and 50% humidity) for reliable data.

- Multiple tests and averaging improve accuracy.

Jiepu provides die-cutting services that customise hook and loop materials to meet your needs.

Nylon (Nylon):

Nylon is strong, durable, and soft.

It has excellent adhesion strength, suitable for repeated use.

It works best for clothing, shoes, and protective gear.

Polyester (Polyester):

Polyester is less costly but has weaker adhesion.

It is resistant to chemicals and heat.

It fits temporary or low-frequency uses like packaging materials.

Nylon And Polyester Mix:

Combines nylon’s softness with polyester’s chemical resistance.

This material is durable and cost-effective.

It is used in industrial equipment and outdoor gear.

Polypropylene (Polypropylene):

Polypropylene is flexible and chemical-resistant.

It suits specialised industrial applications.

PVC (Polyvinyl Chloride):

PVC adds strength and structure as a base layer.

Ideal for products needing strong support.

Rubber (Rubber):

Rubber provides high stickiness and slip resistance.

It’s used in outdoor sports gear and machinery components.

Grade-A Nylon:

This type is soft and gentle on the skin.

Perfect for intimate baby clothing and wearable items.

Non-Snag Materials:

Non-snag only has the loop side, usually paired with Grade-A nylon hooks.

Great for skin-friendly garments.

Choosing the right material ensures optimal performance for your application.

When the Hook and Loop loses its stickiness over time, there are simple ways to restore it.

Start by cleaning the tape.

Use a soft brush, like a toothbrush, to remove dust, hair, and debris.

Soak the tape in warm water with a little mild soap, then rinse it thoroughly.

Let it air dry flat, away from direct sunlight.

You can also repair the hook side.

Use a needle or tweezers to straighten any bent hooks.

Trim off any broken or damaged hooks to improve grip.

To keep your Hook and Loop in good shape, store it properly.

Keep it dry and avoid damp environments.

Use a sealed bag to protect it from moisture.

Store it in a cool, dark place, away from sunlight.

Keep the temperature between 15°C and 25°C, avoiding extremes.

Avoid pressing or squeezing the tape to prevent deformation.

Make sure to keep it clean and free from grease or chemicals.

Store it in a clean container or packaging.

Check it regularly for signs of wear or damage.

When Hook and Loop fasteners get damaged, there are ways to fix them:

First, clean the magic tape.

Use a soft brush like a toothbrush to remove dust and hair from the hook and loop surfaces.

Then, wash the tape in warm water with mild soap, gently rubbing it.

Rinse well with clean water.

If the hooks are bent or damaged, fix them with a needle or tweezers.

Trim off any broken hooks with small scissors.

For extra adhesion, you can use glue.

First, remove any old glue with a scraper or your fingers.

Then, apply a suitable adhesive like superglue or hot glue, and press the tape back into place.

If the stickiness is weak, use double-sided tape or strong adhesive tape on the edges for added support.

For heavy-duty use, stitching the tape can help with durability.

Sew the edges or areas that need extra strength.

Finally, if the tape is beyond repair, replacing it with a new one is the best option.

These methods will help restore your Hook and Loop fastener’s stickiness and extend its life. At Jiepu, we offer die-cutting Hook and Loop services to make sure your materials are perfectly shaped for your needs.

When Using Hook and Loop Fasteners, It’s Important to Avoid:

- Pulling Too Hard: Frequent pulling can wear down the hook and loop surfaces.

- Avoid Sharp Objects: Keep away from pins, nails, or anything that could snag the fasteners.

- High Temperatures: Excessive heat can soften or distort the material, reducing adhesion.

- Moisture: Keep them dry to prevent mildew or bacteria that affect adhesion.

- Chemical Exposure: Avoid contact with harsh chemicals or oils that can damage the fastener.

- Improper Storage: Don’t stack heavy objects on them or fold them, as this can deform the fastener.

By following these simple tips, you can extend the lifespan of hook and loop fasteners, ensuring they perform at their best. Jiepu, with our die-cutting services, ensures high-quality materials are used for long-lasting products.