High Quality Die-Cutting RFI Shielding Tape

- Low MOQ From 300pcs to Support Your Business

- Expert in Die-Cutting RFI Shielding Tape Customization

- Fast Sample Production for Die-Cutting RFI Shielding Tape in Just 3 Days

- ISO14001 Certified

- Product Details

- Application Overview

- Material Insights

- RFI shielding tape reduces EMI and RFI, providing effective solutions for electrical and electronic components.

- The tape contains conductive adhesives to discharge static electricity and prevent dangerous static buildup effectively.

- Durable and corrosion-resistant, it withstands harsh conditions and offers non-flammable properties for added safety.

- Aluminum and copper foil tapes can be die-cut into custom shapes for precise product compatibility.

- These tapes meet RoHS standards, work in wide temperature ranges, and ensure excellent shielding performance.

Jiepu has provided die-cutting services for industries needing RFI Shielding Tape, such as telecommunications, automotive, and defence. This tape blocks harmful electromagnetic waves to protect sensitive electronics.

Telecommunication Equipment:

Used in base stations and servers to prevent external interference. It ensures stable and secure communication.

Automotive Industry:

Applied to control units, sensors, and infotainment systems. It reduces interference between in-car electronics, improving reliability.

Aerospace and Defence:

Used in avionics and military communication devices. It ensures accurate performance in critical systems by blocking interference.

Medical Devices:

Used in monitors and diagnostic tools to block external signals. This helps maintain precise readings and ensures patient safety.

Consumer Electronics:

Applied in smartphones, computers, and home appliances. It protects delicate components from interference, preventing faults.

Electronics Assembly and Repair:

Used on circuit boards to shield high-frequency signals. This ensures proper communication in WiFi, cellular, and RFID devices.

Shielded Rooms:

Used for sealing gaps in shielded enclosures. It blocks outside signals, protecting sensitive equipment from disruptions.

Electronic Components and Cables:

Wrapped around individual parts or wires for long-term protection. It maintains performance and reduces interference risks.

Jiepu, with extensive experience in die-cutting, provides an overview of the key features of RFI Shielding Tape and its benefits.

Conductivity:

The tape contains metal layers like copper or aluminium, which block electromagnetic and radio frequency interference effectively.

Structure Design:

It combines metallised fabrics (e.g., copper-nickel-coated polyester) with conductive adhesives, ensuring strong shielding and durable adhesion.

Surface Resistivity:

With low resistivity (0.03-0.05 Ω/lin.in.), it conducts static charges efficiently, reducing the risk of static build-up.

Shielding Performance:

It achieves high shielding levels, blocking electromagnetic waves across a wide frequency range (e.g., 69dB at 100MHz).

Temperature Resistance:

The tape performs well in extreme conditions, operating between -40˚F and 212˚F (-40˚C to 100˚C).

Flexibility and Compression:

Its flexibility allows it to conform to different shapes, ensuring a tight fit for reliable shielding.

Environmental Compliance:

Many variants meet RoHS standards, meaning they are free of harmful substances and recyclable.

Material Compatibility:

The tape adheres well to various surfaces like metals and plastics, making it suitable for diverse electronic applications.

Physical Design:

Flat or embossed designs optimise conductivity and block electromagnetic waves effectively.

Precise Die-Cutting for RFI Shielding Tape

JIEPU offers tailored die-cutting solutions for RFI shielding tape, ensuring precision and quality for your electronic and security needs. With advanced cutting technology and a wide range of materials, we create customised designs to meet your exact requirements. Our services are ideal for both small and large-scale projects, helping you achieve top performance and faster delivery timelines.

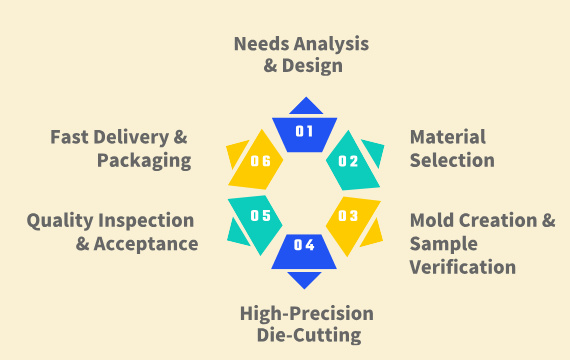

Precise Die-Cutting Process for RFI Shielding Tape

We specialise in advanced die-cutting processes for RFI Shielding Tape, ensuring precision and performance for shielding applications. Using materials like conductive fabrics (copper or nickel-plated) with adhesive backings, we employ methods such as flatbed cutting for thin tapes and rotary cutting for larger designs, achieving accurate shapes tailored to your needs.

Die-Cutting for RFI Shielding Tape with Certified Quality

Jiepu’s die-cutting services are built on strict quality standards. With ISO 9001 certification, every step, from material selection to final inspection, ensures consistent quality for RFI Shielding Tape products. The company also holds ISO 14001 certification, demonstrating its commitment to eco-friendly practices, reducing waste, and conserving resources.

Easy Guide to Requesting RFI Shielding Tape Samples and Getting a Quote

At Jiepu, we make complex processes simple. With over 20 years of experience in die-cutting, we ensure a smooth journey from sample request to final quote. Here’s how it works for RFI Shielding Tape projects.

Sample Request Process

- Tell Us Your Needs

Share details like the size, shape, thickness, material (e.g., copper or aluminium foil), colour, and any special surface treatments. Let us know how you’ll use the tape so we can make it fit your purpose. - Send Your Design

Provide a drawing or a physical sample. This helps us create a precise prototype for you. - Sample Creation

We’ll produce your sample with high accuracy, ensuring the right dimensions and consistent quality. - Sample Delivery

Once the sample is ready, we’ll send it to you along with a tracking email. You can review and test it, then let us know if adjustments are needed. - Supporting Documents

We’ll include material certificates, inspection reports, and technical details to give you a full picture of the sample’s quality.

Quote Process

- Cost Calculation

We calculate costs based on material, mould, production, labour, and any wastage, ensuring full transparency. - Tiered Pricing

We offer pricing based on order size, such as 0–30k, 30–50k, and 50–100k units. For new customers, small sample fees may apply but can be deducted from future orders. - Review the Quote

You’ll receive a detailed quote listing specifications, quantities, unit prices, and delivery timelines. If adjustments are needed, we’re happy to collaborate. - Order Confirmation

Once you approve the quote, we’ll formalise it with a contract that includes all technical and commercial details.

Why Work with Jiepu?

We prioritise accuracy, efficiency, and clear communication at every step. Whether you’re starting with a small test batch or planning large-scale production, Jiepu is your trusted die-cutting partner. Contact us today!

The Shielding Effectiveness Of RFI Shielding Tape Is Measured In Simple Ways:

Shielding Effectiveness Shows How Well The Tape Reduces Electromagnetic Interference.

It Is Measured By Comparing Signal Strengths With And Without The Tape In Place.

The Formula Used Is SE = 20lg(E1/E2), Where E1 Is Signal Strength Without The Tape And E2 Is With The Tape.

Testing Is Done Using Antennas To Measure Signal Reduction.

Tests Are Often Performed In Special Rooms To Block Outside Signals.

The Results Are Shown In Decibels (dB), With Higher Numbers Indicating Better Shielding.

Jiepu Provides Custom Die-Cutting Services For RFI Shielding Tape To Match Your Specific Needs.

When evaluating whether RFI Shielding Tape will meet your bonding needs, you can consider the following factors:

Firstly, there are different types of adhesion to think about. Initial tack refers to how well the tape sticks right after contact, which is useful for quick fixes or temporary applications. Then, there’s the long-term adhesion, which tells you how well the tape holds over time, ideal for permanent installations. Also, peel strength matters if you need to remove the tape easily, such as during maintenance.

Testing adhesion is also essential. Standard tests like the 180° peel or 90° peel test can help measure how strong the adhesion is. These results, usually measured in grams or newtons, can be compared to your specific requirements.

You’ll also need to think about the surface you’re applying the tape to. Whether it’s smooth or rough, metal, plastic, or glass, these surfaces affect how well the tape sticks. Environmental factors like temperature, humidity, and exposure to chemicals can also change how well the tape performs.

Finally, when selecting the right tape, make sure the adhesive properties match your needs. If you require a high bonding strength, choose tape with strong peel resistance. For repeated applications, opt for something with moderate peel strength.

At Jiepu, we offer die-cutting services to help create custom RFI Shielding Tape solutions tailored to your exact specifications. Feel free to consult with us to ensure the best fit for your bonding requirements.

The ability of RFI Shielding Tape to maintain its shielding performance in high-temperature environments depends on the material’s heat resistance and the stability of its shielding effectiveness. Here are a few key factors to consider:

Materials with heat resistance like metal-based tapes, such as aluminium or copper foil tapes, usually maintain their conductivity and shielding ability at higher temperatures.

Some RFI Shielding Tapes use special heat-resistant coatings or substrates, like polyimide films, which can retain stable shielding performance even in hot environments.

To ensure performance, it’s essential to test the shielding effectiveness in high-temperature conditions, as factors like thermal expansion and adhesive performance can affect it.

The adhesive used in RFI Shielding Tape may degrade at high temperatures, leading to tape detachment or reduced shielding effectiveness.

Different products have varying temperature ranges. For example, some may work in environments from -40°C to +150°C, while others can withstand even higher temperatures.

When using RFI Shielding Tape in high-temperature environments, long-term stability, material aging, and other factors like humidity or chemical exposure should also be considered.

For the best performance in such conditions, it’s wise to consult with suppliers and check product specifications. At Jiepu, we provide die-cutting services tailored to your shielding tape needs, ensuring the best fit for your applications.

At Jiepu, we use trusted materials and offer precise die-cutting services to meet your custom needs. Many RFI Shielding Tapes from well-known brands meet ROHS and similar environmental standards. For example, 3M™ Copper Foil EMI Shielding Tape 1125 complies with ROHS 2011/65/EU requirements. Other tapes also clearly indicate compliance with these standards. These tapes are typically designed and manufactured to follow strict environmental regulations.

RFI shielding tape usually has excellent flexibility, making it ideal for various surfaces.

For example, metalized fabric shielding tape easily conforms to complex geometric shapes.

Copper foil tape also offers great flexibility, fitting irregular surfaces with ease.

This flexibility ensures the tape provides effective shielding performance while staying easy to install.

Jiepu offers expert die-cutting services to ensure each tape is perfectly tailored to your needs.