Automotive Die Cutting Solution

At Jiepu, we provide high-quality die-cutting solutions for the automotive industry, including adhesive tapes, noise reduction components, and interior cushioning parts.

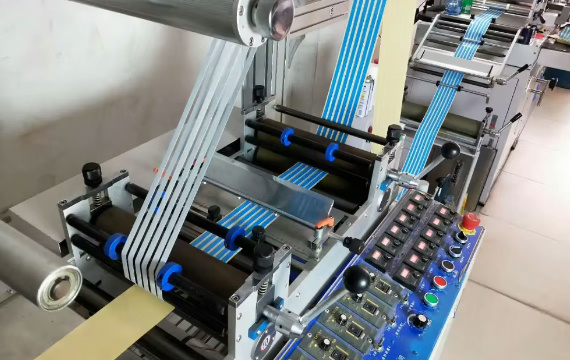

Our advanced equipment ensures precision, reliability, and high-volume production to meet your needs.

Die Cutting Solutions for the Automotive Industry

Jiepu delivers advanced die-cutting solutions for the automotive sector, focusing on reducing BSR (buzz, squeak, and rattle) and improving NVH (noise, vibration, and harshness). Our solutions also support lightweight designs for better fuel efficiency and incorporate heat-resistant materials for optimal thermal management.

With ISO 9001, ISO 14001, and IATF 16949 certifications, we guarantee high-quality, precision components that meet OEM standards, from rapid prototypes to final production.

Key Automotive Technology and System Categories

Innovative solutions for electric vehicles and battery systems, driving sustainability and performance in the automotive sector.

Advanced digital displays for intuitive, high-quality driver interfaces, enhancing both functionality and user experience.

Advanced Driver Assistance Systems focus on improving safety with technologies like lane-keeping, collision avoidance.

Sophisticated automotive interiors designed for comfort, style, and functionality, offering enhanced user experiences and ergonomic designs.

Stylish and durable exterior components that improve aerodynamics, safety, performance, efficiency, functionality, and aesthetics of modern vehicles

High-performance automotive lighting solutions, providing improved visibility, energy efficiency, and design innovation for modern vehicles.

Applications of Materials in Automotive

Lightweight, durable, and versatile material for automotive insulation and cushioning.

Strong, durable adhesive for automotive bonding, sealing, and assembly applications.

Effective material for reducing electromagnetic interference in automotive electronics.

Heat-resistant, durable adhesive tapes for automotive insulation and EMI shielding applications.

An efficient heat dissipation solution for automotive electronics and components ensuring reliability.

Durable, flexible material for seals, gaskets, and vibration dampening in automotive applications.

Trusted Partners in Automotive Die Cutting

At Jiepu, we partner with world-renowned brands to ensure top-quality materials for automotive die-cutting. Our key partners include UPM in paper and forest solutions, 3M in diversified technologies, and DuPont in chemical materials. In electronics and industrial equipment, we work with SONY and POLYONICS. For adhesive tapes and labels, our trusted suppliers are Tesa, KING LABEL, LINTEC, and NITTO DENKO. In labels and packaging, we collaborate with FASSON (Avery Dennison) and DENVISYN. These strong partnerships enable us to deliver innovative and reliable solutions tailored to your needs.

Precision Die-Cutting for Automotive Quality & Efficiency

20+ years of experience delivering high-precision solutions for automotive parts.

3 million parts daily with on-time delivery and strict quality control.

Advanced testing ensures zero defects and high durability.

Engineers provide tailored solutions and full technical support.

Compliant with ISO and IATF 16949 for reliable automotive parts.

Custom die-cutting services for small and large production runs.

Additional Die-Cutting Materials for Automotive Electronics and More

we specialize in providing precise die-cutting solutions for a wide range of automotive components, catering to both small batches and high-volume production.

Interior Components

We manufacture essential parts such as:

- Pressure-sensitive adhesive films

- Sound insulation materials

- Vibration dampening materials

- Gaskets and sealants

- Anti-squeak and anti-vibration tapes

- Nonwoven fabrics and flocking

Exterior Components

Our die-cut solutions for exterior parts include:

- Scratch and impact protection materials

- Thermal insulation and heat management components

- Embossed shielding materials

- Body styling and trim installations

- Surface and paint protection materials

Door/Window Systems

We also provide die-cutting for:

- Seals and soundproofing materials

- Thermal management parts

- Weatherproof sealing solutions

Electronics

For automotive electronics, we offer:

- Insulation for electronic components and batteries

- Thermal management solutions

Whether for new vehicle applications or aftermarket parts, our die-cut solutions are designed to meet the highest quality standards in the automotive industry.

Automotive Die Cutting Is Widely Used In Many Interior Parts Of A Car. Here Are Some Common Applications:

- Soft Materials Are Used On Door Panels To Make Them Look Good And Feel Comfortable.

- Seat Covers Are Made From Die-Cut Materials Like Leather, Fabric, Or Synthetic Materials For Comfort And Support.

- Dashboards Are Covered With Soft Or Hard Materials To Improve Appearance And Function.

- The Roof Lining Uses Materials That Offer Good Soundproofing And Heat Insulation.

- Carpets And Mats Provide A Comfortable Feel For The Feet And Help With Noise Reduction.

- Sun Visors And Vanity Mirrors Often Have Die-Cut Parts For Decorative Edging.

- Storage Compartments And Cup Holders Use Soft Materials To Reduce Noise From Items Moving Around.

- Armrests On Doors And Centre Consoles Are Covered With Soft, Comfortable Materials.

- Air Vents Have Die-Cut Materials For Decorative Frames And Blades.

- The Centre Console Panel Uses Die-Cut Materials For Decoration And Button Backlighting.

- Door Handles And Window Controls Have Die-Cut Components For A Better Feel And Appearance.

- Speakers And Navigation Systems Use Die-Cut Materials For Protection And Decoration.

- Seat Belts Have Cushioned Die-Cut Pads And Decorative Elements.

- Interior Lighting Has Decorative Covers Made From Die-Cut Materials.

- Window Frames Are Trimmed With Die-Cut Parts For A Clean Look.

When Choosing The Right Die-Cutting Materials, We Consider Factors Like Durability, Appearance, Comfort, And Cost. At Jiepu, We Provide High-Quality Die-Cutting Services For Automotive Parts, Helping To Improve Both The Aesthetics And Functionality Of Your Car’s Interior.

Die-Cutting Materials Play A Crucial Role In Soundproofing And Heat Insulation In Cars. Here Are Some Key Applications:

- Foam Is Widely Used For Insulation, Noise Reduction, And Cushioning. Closed-cell Foam Is Water-Resistant And Seals Areas Like Windows And Doors, While Open-cell Foam Helps Reduce Noise Inside The Car.

- Rubber Materials, Like EPDM, Are Used In Seals And Gaskets To Keep Water, Dust, And Air Out, Improving Insulation And Comfort Inside The Car.

- Felt Is Often Used For Its Insulating Properties And Ability To Reduce Noise And Vibration. It Is Commonly Found On The Car Floor, Roof, And Door Panels.

- Nonwoven Fabrics Are Used For Soundproofing And Insulation. These Are Typically Found In Roof Linings, Carpets, And Door Panels, Helping To Cut Down On Noise And Vibration.

- Metal Foils, Like Aluminium, Are Used For Heat Shields, EMI Shielding, And Other Protective Layers. Aluminium Is Lightweight And Reflects Heat, Making It Ideal For Car Insulation.

- Polyurethane Foam Is Lightweight And Mouldable, Often Used In Engine Bay Areas And Under Bonnet Insulation To Reduce Vibration And Noise.

- Bonnet Linings, Made From Baynat® Polyurethane, Replace Traditional Felt, Offering Better Sound Absorption And A Lighter Weight.

- Sealing Gaps And Voids In Key Areas Of The Car Body Helps Change The Path Of Vibration, Reducing Resonance And Improving Ride Comfort.

- These Die-Cutting Materials Help Improve A Car’s NVH (Noise, Vibration, Harshness) Performance, Making The Driving Experience More Comfortable For Everyone.

Automotive Die Cutting Materials Are Essential For Shock Absorption, Insulation, And Component Fixing In Automotive Electronics. Here’s How They Work:

- Foam Tapes Are Used For Sealing And Cushioning Parts, Reducing The Need For Bolts And Screws, While Ensuring Strong Adhesion In Automotive Die Cutting Applications.

- Nonwoven Fabrics Are Perfect For Filtration, Insulation, And Soundproofing. These Die-Cut Materials Are Found In Roof Linings, Carpets, And Door Panels To Minimise Noise And Vibration.

- Metal Foils, Like Aluminium And Copper, Are Commonly Die-Cut To Form Heat Shields And EMI (Electromagnetic Interference) Barriers, Protecting Electronics And Reflecting Heat.

- Damping Foils And Electrical Tapes Are Die-Cut To Provide Electrical Insulation And Shield Electronics From External Interference, Enhancing The Durability Of Automotive Systems.

- Custom-Cut Soundproofing Materials, Made From Foam, Felt, Or Textiles, Are Used Between Parts To Reduce Noise And Vibration, Ensuring A Quieter Ride.

- Protective Cushioning Materials, Such As Roof Sealing Tapes, Safeguard Electronics From Impact And Vibration, While Offering Insulation And Extending The Product’s Lifespan.

- Plastics, With Excellent Insulation And Durability, Can Be Die-Cut For Custom Parts Like Protective Films And Insulation Layers, Vital For Automotive Electronics.

- Hot-Melt Tapes, Die-Cut For Fast Bonding, Are Ideal For Quick Assembly In High-Temperature Automotive Environments.

- These Automotive Die Cutting Materials Ensure That Electronics Perform Reliably In Challenging Conditions, Reducing Noise, Vibration, And Enhancing Safety.

Die-cut materials improve car quality in automotive manufacturing in several ways:

Safety

Die-cut materials enhance car safety by producing seals and gaskets for components like engines and transmissions. These seals prevent leaks, ensuring vehicle safety. Jiepu’s precision die-cutting ensures reliability and effectiveness.

Comfort

Die-cut materials such as foam and felt improve comfort by providing sound insulation and heat resistance, especially in seats, headrests, and dashboards. Jiepu’s solutions help create a more comfortable driving experience.

Durability

Die-cut materials like EPDM rubber protect the vehicle from external elements like water and dust. Jiepu’s die-cutting enhances the durability and longevity of automotive parts.

Heat Insulation

Jiepu’s die-cut materials, including felt and metal foils, offer heat protection for components near the engine or exhaust, improving vehicle performance and durability.

Energy Efficiency

Lightweight die-cut components reduce the car’s weight, improving fuel economy and extending battery life for electric vehicles. Jiepu’s solutions support better energy efficiency.

Manufacturing Precision

Jiepu’s die-cutting technology ensures precise parts that meet automotive industry standards, enhancing production quality and reducing errors.

Waste Reduction

Jiepu’s precise die-cutting reduces material waste, helping manufacturers save costs and support sustainable production.

Environmental Sustainability

Jiepu is committed to eco-friendly die-cutting solutions that reduce waste and support green manufacturing practices.

Adhesive Performance

Jiepu’s die-cutting enhances adhesive strength, ensuring critical components stay securely in place for improved vehicle performance.

In Automotive Electronics, Die-Cut Materials Ensure Precision And Reliability In Several Ways:

We carefully select materials that can handle tough automotive environments, such as high temperatures and chemicals. For example, plastics are durable, lightweight, and resistant to corrosion, making them ideal for protective films and insulation layers.

The die-cutting process uses specialised tools to cut and shape materials with great accuracy. This allows us to mass-produce parts that meet strict industry standards.

We apply advanced techniques like flatbed, rotary, and laser die-cutting to achieve precise results for automotive components, ensuring they meet the highest requirements.

Quality control is crucial. We perform regular checks, tests, and keep detailed records to ensure that every part performs reliably over time.

Die-cut materials, such as metal foils, offer excellent conductivity and heat resistance. These materials are used in components that need electromagnetic shielding, conductivity, or heat dissipation.

Foams and felts are used to protect sensitive electronics from shock and vibration while also providing insulation, extending the lifespan of components.

Optical films are used for displays and lenses, improving clarity and protecting surfaces from damage.

Protective films are applied to safeguard surfaces from scratches and contamination, maintaining the product’s appearance and function.

Through these methods, die-cut materials ensure that automotive electronics are both precise and reliable, contributing to better performance and safety.