Premier Quality Die-Cutting EMI Shielding Tapes

- For more than 20 years, Jiepu has been providing high-quality Die-Cutting EMI Shielding Tapes

- ISO9001 & ISO14001 Certification

- Flexible MOQ for Your Custom Die-Cutting EMI Shielding Tapes Needs

- Applicable to various fields

- Product Details

- Application Overview

- Material Insights

- EMI shielding tapes block or redirect electromagnetic waves effectively, offering shielding performance of 80-110dB.

- Made from conductive materials like copper, aluminum, or tin/copper for reliable grounding.

- Copper-based or tin/copper tapes resist corrosion for long-lasting use, resisting chemicals and outdoor aging.

- Available in materials like copper foil, aluminum foil, and conductive fabric.

- Help products meet strict EMI and EMC regulations in aerospace, medical, and military industries.

Jiepu, with years of experience in die-cutting, has provided solutions for industries that require EMI Shielding Tapes to protect sensitive electronics from interference.

- Electronics and Telecommunications: EMI Shielding Tapes are used to protect circuit boards, connectors, and cables from electromagnetic interference (EMI), ensuring smooth operation of devices like phones and computers.

- Aerospace and Defence: These tapes are applied in radar systems, communication equipment, and military vehicles to maintain reliable performance in environments with high electromagnetic activity.

- Medical Devices: Used in MRI machines, pacemakers, and other medical equipment, EMI Shielding Tapes protect against external interference, ensuring accurate and safe operation of medical devices.

- Industrial and Manufacturing: These tapes help protect sensitive equipment, such as control panels and data systems, from EMI generated by electrical and mechanical systems.

- Renewable Energy: In solar panels, wind turbines, and energy storage systems, EMI Shielding Tapes prevent interference that could disrupt their performance.

- Automotive and Transport: Used in car wiring, sensors, and displays, these tapes reduce electromagnetic interference, improving the reliability and performance of automotive electronics.

- Copper Foil Tapes: Known for their excellent conductivity, these tapes are used in devices like phones and computers to block EMI.

- Aluminum Foil Tapes: Lightweight and cost-effective, these tapes are commonly used in aerospace and telecom to reflect electromagnetic waves.

- Conductive Fabric Tapes: Flexible and adaptable, these tapes are perfect for shielding curved or irregular surfaces in electronics.

- Conductive Foam Tapes: Made from soft materials with conductive particles, these tapes are ideal for flexible EMI protection in the electronics industry.

- Flame-Retardant EMI Shielding Tapes: These tapes not only block EMI but also resist high temperatures, making them suitable for automotive and construction applications.

- Mu-Metal Shielding Tape: With high magnetic permeability, Mu-Metal tapes are used in electronics and transformers to shield against magnetic interference.

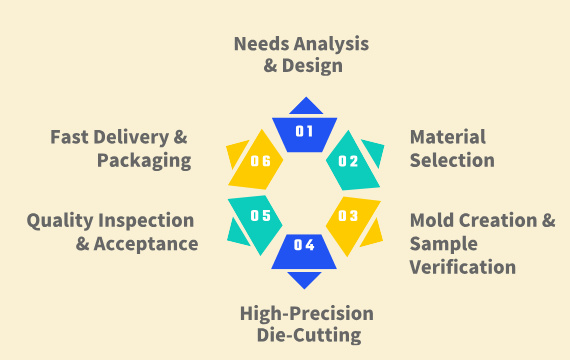

Efficient Die-Cutting Process for EMI Shielding Tapes

Based on Jiepu’s expertise, commonly used processes for EMI Shielding Tapes include precise material selection and mould design.

High-quality materials like aluminium or copper foils are inspected for flaws to ensure they meet shielding and durability requirements.

Our advanced moulding techniques, such as laser cutting, create precise dies tailored to the tape’s thickness and performance needs.

The die-cutting process—whether flatbed or rotary—ensures accurate shapes for even complex designs, maintaining the tape’s shielding effectiveness.

High-Quality Die-Cutting Services with EMI Shielding Tapes

At Jiepu, we specialise in delivering precision die-cut solutions and EMI Shielding Tapes that meet the highest standards.

Backed by ISO 9001, ISO 14001, and IATF 16949 certifications, our products are designed to exceed customer expectations for quality, sustainability, and performance.

Our EMI Shielding Tapes use conductive materials like aluminium, copper, and tin-plated copper, offering excellent shielding for PCB components, cables, and more. Custom sizes and shapes are available to suit your specific needs, ensuring effective solutions for managing electromagnetic interference.

Sample Request and Quotation Process for EMI Shielding Tapes

Your Partner in EMI Shielding Solutions For over 20 years, Jiepu has been your go-to for precision die-cutting services. Let’s break down the process of getting your EMI Shielding Tapes samples and quotes in a way that’s easy to understand.

1. Needs Communication First things first, we chat about what you need for your EMI Shielding Tapes—like size, thickness, and where they’ll be used. This helps us understand your project’s specifics.

2. Sample Requests You can ask for samples to test out. We’ll craft a preliminary sample based on your drawings or specs, ensuring it meets your expectations.

3. Drawing Confirmation and Process Design We’ll check if your design is ready for mass production, using our years of experience. We’ll also make sure we’ve got the right materials for the job.

4. Quotation Process Our报价 includes direct costs, production costs, manufacturing costs, and a bit extra for us. It’s all straightforward and transparent.

5. Sample Making and Testing We’ll make you a sample to test, ensuring it meets performance requirements. We can even add backing or heat treatment if needed.

6. Moving to Mass Production Once you’re happy with the sample, you place an order, and we start mass production. We’ll work around your schedule to get it done.

7. Quality Control and Certification We don’t send anything out without a thorough check. We’ve got the certificates to prove our products are safe and eco-friendly, like RoHS compliance.

8. After-Sales Service We’re here for you even after you’ve got your order. Any issues? Just give us a call.

9. Storage Conditions Keep your EMI Shielding Tapes in the right temperature and humidity to keep them in top shape.

10. Special Requests If you need something extra, like a specific temperature range or shielding effect, just tell us. We’ll make it happen.

11. Eco-Friendly and Compliant Our tapes are RoHS compliant, meaning they’re safe for the environment and free from harmful substances.

12. Custom Services We offer custom services, from laminating to sticking different types of foam, all made to your liking.

By following these steps, you get EMI Shielding Tapes that fit your needs perfectly. Each step is designed to ensure your product performs well, meets quality standards, and is compliant with regulations.

EMI Shielding Tapes are special tapes designed to protect sensitive electronic components and devices from electromagnetic interference (EMI).

They typically consist of a conductive backing material, such as copper or aluminium, and a pressure-sensitive adhesive, making them easy to apply to various surfaces.

The conductive backing acts as a barrier that blocks or redirects electromagnetic waves, preventing interference with electronic equipment.

These tapes are used in industries like electronics, telecommunications, aerospace, and medical devices, helping to maintain signal integrity, extend the lifespan of components, and offer design flexibility.

EMI Shielding Tapes are also a cost-effective solution compared to other methods, such as conductive coatings, as they are easy to apply to specific areas, reducing material costs and the need for time-consuming redesigns.

At Jiepu, we provide die-cutting services for such materials, ensuring a precise and tailored fit for your needs.

EMI Shielding Tapes work to block electromagnetic interference in several ways.

When electromagnetic waves meet the shielding material, most of them are reflected back due to a difference in impedance.

Some waves that get through are absorbed by the metal material, which turns their energy into heat, reducing their strength.

The tapes use reflection, absorption, and dispersion to break up the waves and prevent interference between devices.

The conductive layer in the tape creates a continuous path, guiding the waves away through grounding.

EMI Shielding Tapes can be connected to the device’s ground, allowing the collected charges to safely dissipate.

The tapes also seal gaps or openings in devices to prevent electromagnetic waves from leaking or entering.

In some cases, multiple layers of different metals are used for extra protection against both high and low-frequency interference.

To fill gaps between parts, conductive elastic materials are added, ensuring no electromagnetic leakage.

These tapes can be tailored to block specific frequencies, offering custom shielding solutions.

By using these methods, EMI Shielding Tapes help protect electronic devices, ensuring stable signals and reliable performance.

There are various types of EMI Shielding Tapes, each with unique properties and applications.

Copper foil tape is highly conductive and offers excellent adhesive properties. It is used in critical applications like electronic devices, circuit boards, and electrical grounding.

Aluminium foil tape provides strong shielding against radio frequencies and is commonly used in industries like aviation, telecommunications, and medical equipment.

Conductive fabric tape is made from flexible fabric material and is known for its adaptability. It’s ideal for shielding curved or irregular surfaces.

Conductive foam tape contains soft, flexible material with conductive particles, making it great for flexible applications in electronics.

Flame-retardant EMI shielding tape is made from special materials that not only protect against EMI but also resist high temperatures, making it suitable for automotive and construction industries.

Metalized fabric tape uses copper-coated tear-resistant fabric as the backing, providing a lightweight, conductive, and flexible shielding solution.

Double-sided conductive tape has conductive adhesive on both sides, offering excellent grounding and conductive surface connections, with low thermal resistance.

Non-conductive adhesive copper foil tape uses a smooth backing with a non-conductive adhesive. It’s suitable for applications like connector and cable shielding, grounding, and static shielding.

Tin-plated foil-backed tape offers excellent solderability, corrosion resistance, and conductivity, making it ideal for use in harsh environments.

Embossed foil-backed tape has a textured pattern that ensures stable contact resistance and high shielding performance.

These different types of EMI Shielding Tapes can be chosen based on your specific needs to ensure optimal shielding and performance. At Jiepu, we provide die-cutting services to help tailor these materials for your unique requirements.