High Quality Die-Cutting Foil Heat Shield

- Leading Die-Cutting Foil Heat Shield manufacturers, customize any Foil Heat Shield for your project

- ISO9001 certified, any size, style, design, color can be customized to meet your needs

- Applicable to various fields

- Quick Samples from China

- Product Details

- Application Overview

- Material Insights

- Foil heat shield reflects and isolates heat to lower temperatures and protect equipment effectively.

- Jiepu foil heat shield meet FMVSS-302 flame resistance standards, ensuring safe usage.

- Ultra-thin options, as slim as 0.5mm, require minimal installation space.

- Handles temperatures up to 500°C, suitable for extreme heat applications.

- Some high-density graphite models offer excellent thermal and electrical conductivity.

Jiepu has provided die-cutting services in various fields, including automotive, aerospace, construction, and industrial applications.

Foil Heat Shield is used widely across industries to protect sensitive components from heat. In cars, it’s used to shield engine parts, fuel tanks, and mufflers from excessive heat. In aerospace, it protects spacecraft during re-entry and shields engine parts in racing cars. For buildings, it helps insulate roofs and walls, improving energy efficiency. In industrial settings, it keeps machinery safe from high temperatures.

This material is highly reflective, lightweight, and can withstand temperatures up to 650°C, making it ideal for heat protection. Its flexibility allows it to be easily cut and installed, and some versions are fire-resistant, enhancing safety.

Jiepu, with years of die-cutting experience, introduces the key features of various Foil Heat Shield materials.

ZircoFlex® FOIL is a flexible ceramic material that reduces heat by up to 85%. It’s lightweight, can be bent without damage, and comes in different thicknesses for easy cutting and installation.

ZircoFlex® GOLD has a gold-coated backing that reflects up to 98% of heat. It’s also flexible, lightweight, and easy to cut and install, offering great protection against both radiant and conducted heat.

Metallized Polyimide is a lighter and more flexible alternative, ideal for complex or hard-to-reach areas. Its excellent heat resistance makes it suitable for extreme temperatures, like in aerospace applications.

Custom Die-Cut Solutions with Foil Heat Shield

At Jiepu, we offer customised die-cut solutions that incorporate Foil Heat Shields, tailored to meet the needs of industries like automotive electronics and security. Our services ensure precise cutting, personalised designs, and high-quality materials, all aimed at enhancing product performance. Whether you require small or large production runs, we provide flexible solutions to help reduce costs, improve product quality, and speed up time-to-market.

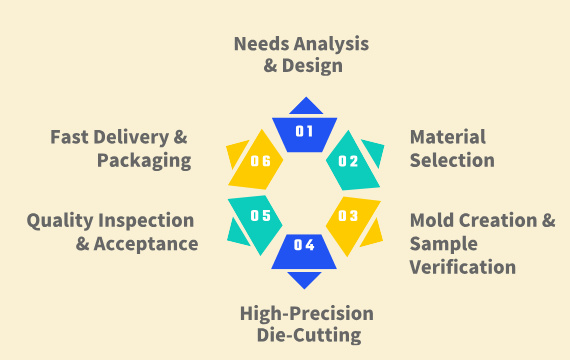

Precision Die-Cutting Process for Foil Heat Shields

At Jiepu, we frequently use precise die-cutting processes for Foil Heat Shields, ensuring accurate shapes and reliable performance. The process begins with material preparation, where high-quality aluminium foil is inspected to ensure no defects like holes or creases, as these impact heat resistance.

Next, we design a custom mould based on the shield’s thickness and size. Using techniques like flatbed cutting for thin foils or rotary cutting for larger pieces, we achieve clean, precise cuts. Additional steps, such as punching holes or shaping, ensure the final product meets specific requirements.

Certified Die-Cutting Services with Foil Heat Shields

We provide high-quality die-cutting services, supported by ISO 9001 for quality, ISO 14001 for environmental care, and IATF 16949 for the automotive industry. These certifications ensure that our services meet international standards, delivering reliable, efficient, and environmentally responsible solutions.

Our Foil Heat Shields are made from high-performance materials like aluminium foil, designed to reflect heat and protect equipment from overheating. We offer custom sizes and fast sample delivery, meeting the unique needs of our clients.

Simple Steps for Foil Heat Shield Samples and Quotations

At Jiepu, we bring 20+ years of die-cutting expertise to make requesting samples and getting quotes for Foil Heat Shields easy. Here’s our straightforward process:

- Drawing Check: We review 2D drawings for accuracy, making sure all details like dimensions and materials are clear for hassle-free production.

- Material Availability: We prioritise using easily sourced materials to avoid delays and ensure smooth workflows.

- Process Planning: Our experts analyse production steps, considering part complexity and alignment needs for assembly.

- Quick Quotation: Receive a detailed quote in 24 hours, calculated based on order size and complexity. For larger orders, tooling fees can be refunded.

- Fast Sample Creation: Samples are produced in 72 hours, following precise specifications and quality standards.

- Thorough Inspection: Every sample goes through strict quality checks, with a full measurement report included.

- Delivery of Samples: Samples, along with necessary documentation like certifications, are shipped promptly for review.

- Production Confirmation: Once the sample is approved, mass production begins with regular inspections to ensure top quality.

- Timely Delivery: Products are carefully packed, delivered on time, and followed up to meet your production needs.

Jiepu’s efficient process ensures accurate quotes and high-quality Foil Heat Shield samples, keeping your project on track. Let’s collaborate for success!

The name “Foil Heat Shield” comes from the materials used and their purpose as effective heat protection solutions. Here’s a simple breakdown:

Metal Foil Base: The “Foil” refers to the main material, usually metal foil like aluminium, known for being thin, lightweight, and great at reflecting heat.

Heat Protection: “Heat Shield” highlights its role in blocking heat transfer and protecting components, such as engine parts, from high temperatures.

Flexible and Lightweight: These shields are thin and bendable, allowing them to fit different shapes and even fold without losing their protective qualities.

Metal Backing: Many Foil Heat Shields have a metal backing, making them sturdy and easy to handle during installation.

Easy to Cut and Install: They can be cut by hand or machine and secured with mechanical fasteners or high-temperature adhesives.

Excellent Heat Resistance: Foil Heat Shields provide outstanding thermal protection. For example, ZircoFlex® FOIL can reduce heat transfer by up to 85%.

In short, the name “Foil Heat Shield” reflects their key characteristics: made from metal foil and designed for effective heat protection.

Aluminium Foil Heat Shields

Pros:

- Heat Reflection: Aluminium foil effectively reflects radiant heat, bouncing it back into the environment.

- Insulation: Its layered structure reduces heat conduction and convection, offering good thermal insulation.

- Moisture Resistance: Aluminium foil is waterproof, keeping insulation materials dry and effective.

- Fire Resistance: It enhances the fireproofing of insulation materials when applied as a surface layer.

- Durability: Aluminium foil adds strength to insulation materials, increasing their lifespan.

- Eco-Friendly: Many aluminium-based materials are recyclable and help reduce energy consumption.

Cons:

- Higher Cost: Aluminium foil insulation tends to be more expensive than basic alternatives.

- Limited Applications: Despite its properties, it is rarely used for large-scale wall insulation due to its cost.

Ceramic Heat Shields

Pros:

- High-Temperature Tolerance: Ceramic heat shields can withstand extreme temperatures, making them ideal for high-heat environments.

- Versatile Forms: Rigid ceramic tiles and flexible ceramic blankets suit various applications.

- Ablation Resistance: Some ceramics, like ZrB2-ZrC, are excellent for environments requiring erosion resistance, such as hypersonic vehicles.

- Superior Insulation: High porosity in ceramics results in excellent heat-blocking performance.

Cons:

- Brittleness: Rigid ceramic tiles are prone to cracking and can be hard to repair.

- Thermal Expansion Issues: Ceramic materials can expand differently from aluminium, causing stress during high-temperature exposure.

- Complex Handling: While the technology for ceramic shields is advanced, their fragility and technical demands can complicate maintenance.

Both aluminium foil and ceramic heat shields have strengths tailored to specific uses. Aluminium is lightweight, reflective, and moisture-resistant, while ceramics excel in high-temperature endurance and advanced aerospace applications. Choosing between them depends on your environmental and performance needs.

Foil Heat Shields are used in many areas beyond spacecraft, offering valuable heat protection in different industries.

In cars, they help block heat and noise. These thin, flexible materials can be shaped to fit around engines, exhaust systems, and interiors. Car makers use them to protect parts from high temperatures and damage, while also reducing noise levels for a quieter ride.

In heating and air conditioning systems, Foil Heat Shields are key to keeping systems efficient and running smoothly. Their lightweight, corrosion-resistant, and heat-resistant properties make them ideal for use in ducts and HVAC units.

In buildings, these shields improve insulation and energy efficiency. For example, they’re often installed in roofs to reflect sunlight, keeping indoor spaces cooler and cutting down on energy use.

In factories, they protect machines from overheating, making workplaces safer and more efficient. By reducing heat transfer, they help maintain stable conditions for operations.

For electronics, high-performance foil materials manage heat in devices like computers and phones. Some types, like SIGRATHERM® foil, are made of special graphite that spreads heat evenly without adhesives, improving performance and lifespan.

For batteries, these foils also play a role in keeping them cool, which is essential for safety and reliability.

These examples show how Foil Heat Shields are vital in protecting and improving a wide range of products and systems.

Smart Photovoltaic Window Films

A breakthrough in this field integrates organic perovskites with tungsten-doped vanadium oxide nanoparticles (W-VO₂ NPs) into smart photovoltaic window films. These films not only generate electricity but also regulate solar heat entering buildings, improving indoor climates. At 25°C, they achieve a power conversion efficiency of 15.4%, increasing to 16.1% at 45°C. Their 25.5% average visible light transmission and advanced infrared modulation outperform commercial low-emissivity glass in energy efficiency.

Transparent Insulating and UV-Blocking Coatings

A new transparent coating has been developed to enhance glass windows’ energy efficiency. Using titanium dioxide hollow spheres, the film achieves 75% visible light transmission, blocks UV entirely, and offers excellent thermal insulation with a conductivity of 0.142 W/(m·K). This combination reduces heat transfer without sacrificing clarity.

Electromagnetic Shielding Films for Induction Heating

Electromagnetic shielding films are used in induction heating systems to optimise energy use. Research shows that films with metal powder composites and ferrites offer improved heating efficiency. Nanocrystalline films are particularly noteworthy, achieving maximum efficiency with specific magnetic permeability levels, making them highly effective in energy conservation.

Micro/Nanomanufacturing for Building Facade Materials

Advanced techniques like coating, evaporation deposition, and nanolithography are being used to produce facade materials for thermal management in buildings. These methods enhance the energy performance of structures by reducing heat transfer and improving insulation.

High-Efficiency Transparent Vacuum Insulation

Vacuum Insulated Glass (VIG) is a cutting-edge technology that significantly reduces heat transfer through windows. It offers thermal conductivity as low as 0.5 W/m²·K, outperforming traditional double glazing and gas-filled units. This innovation is a game-changer in reducing building energy use.

These exciting advancements show how Foil Heat Shields contribute to energy efficiency and sustainability. At Jiepu, we specialise in providing tailored die-cutting solutions that enable the precise manufacturing of materials for these applications.