Top Quality Die Cutting Foil Tapes Provider

- Customize various sizes For Die Cutting Foil Tapes Provider

- Fast Sample Production for Foil Tapes Provider in Just 3 Days

- ISO14001 Certified Foil Tapes Die-Cutting Production

- Over 20 years of Die Cutting experience

- Product Details

- Application Overview

- Material Insights

- Foil Tapes are fire-resistant and meet UL 746C and UL 723 standards.

- Some, like 3M™ Aluminum Foil Tape 425, work up to 149°C long-term.

- Foil Tapes block moisture effectively, making them great for sealing.

- The aluminum surface reflects heat and light, useful for thermal insulation.

- They resist UV rays and chemicals, suitable for indoor and outdoor use.

- Foil Tapes meet RoHS standards and contain no harmful materials.

- Aluminium Foil Tape with Paper Backing: Used for sealing HVAC system joints and insulating materials like rock wool, protecting against moisture and corrosion.

- Aluminium Foil Tape without Paper Backing: Designed for fast bonding, typically used in sealing HVAC system joints.

- Water-Based Adhesive Aluminium Foil Tape: Features low toxicity, suitable for indoor insulation and general repairs.

- Solvent-Based Aluminium Foil Tape: Highly durable, perfect for outdoor use or extreme conditions.

- Acrylic Pressure-Sensitive Aluminium Foil Tape: Offers excellent long-term adhesion, ideal for outdoor applications.

- Fibreglass Reinforced Aluminium Foil Tape: Offers great moisture resistance, commonly used for sealing pipes and insulating HVAC ducts.

- Flame Retardant Aluminium Foil Tape: Blocks heat and fire, often used for insulation in walls and steel frames.

- Copper Foil Tape: Primarily used for electromagnetic shielding in electronics, providing excellent conductivity and protection against EMI.

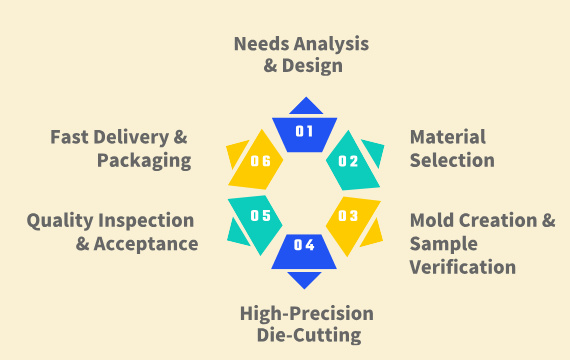

Precision Die-Cutting Process for Foil Tapes

Our expertise lies in crafting tailored die-cut solutions for Foil Tapes.

These tapes, made from metal foils like aluminium or copper combined with pressure-sensitive adhesives, require careful handling.

Based on Jiepu’s extensive experience, we first select and inspect high-quality foil materials to ensure they meet strict standards—free from creases or defects.

Using precision-engineered moulds designed for the metal’s hardness and flexibility, we achieve clean and accurate cuts every time.

Certified Foil Tape Die-Cutting Services

Jiepu offers high-quality Foil Tape die-cutting services, fully certified with ISO 9001, ISO 14001, and IATF 16949 standards.

This guarantees that our products are not only eco-friendly and durable, but also meet the strict quality requirements of the automotive industry.

Our Foil Tapes provide excellent conductivity, heat resistance, and are customised to meet specific client needs, ensuring reliable performance in demanding environments.

Foil Tapes: Easy Steps for Sample Request and Quotation

At Jiepu, we make the process of ordering Foil Tapes as simple and straightforward as possible. Here’s how it works:

1. Share Your Requirements

Let us know the size, thickness, adhesive strength, and application of the Foil Tapes you need.

2. Request Samples

You can ask for samples to test and check that the product meets your needs. We will produce a sample based on your drawings or specifications.

3. Confirm Drawings and Process Design

We check the drawings to ensure they are ready for mass production. We also design the process to ensure smooth production while maintaining consistent quality.

4. Get Your Quote

We provide a quote based on the cost of materials, production time, and other processing factors.

5. Sample Production and Testing

We create samples for you to test and confirm they meet your requirements. Customisation options like fabric backing or heat treatment are available.

6. Mass Production

Once the sample is approved, we begin bulk production based on your order volume and delivery timeline.

7. Quality Control and Certification

We perform strict quality control checks and provide necessary certifications such as RoHS, ensuring the product meets environmental and safety standards.

8. After-Sales Support

We offer full after-sales service, including professional support to solve any issues quickly and efficiently.

9. Storage Conditions

To keep Foil Tapes in top condition, we recommend storing them in a stable environment with proper temperature and humidity levels.

10. Special Requests

If you need something specific, such as temperature resistance or shielding performance, just let us know, and we will tailor the product to meet your needs.

11. Environmental Compliance

We ensure our Foil Tapes comply with RoHS standards, meaning they are free from harmful substances.

12. Customisation Services

We offer custom services such as laminating, adhesive foam bonding, and manual crafting based on your specifications.

By following these simple steps, you can be confident that your Foil Tapes will meet your exact needs, with reliable performance and top-quality standards.

Foil Tapes are typically made from metal materials, and they can be made from a few different types, such as:

- Aluminium Foil: This is the most common type, with a layer of aluminium and either a rubber or acrylic adhesive.

- Copper Foil: Used mainly for electromagnetic shielding, copper foil tape takes advantage of copper’s excellent conductivity.

- Bronze: A copper-tin alloy that is strong, corrosion-resistant, and has good thermal and electrical conductivity.

- Silver Foil: Known for its excellent shielding properties, silver foil also has antibacterial and anti-oxidation qualities.

- PVC: Some foil tapes are made with PVC, which acts as a fire-resistant base and can block moisture from above.

These materials give Foil Tapes different characteristics, such as temperature resistance, waterproofing, and electromagnetic shielding. At Jiepu, we provide die-cutting services for a range of materials, including foil tapes, to meet your needs.

Yes, Foil Tapes are generally suitable for bonding on curved surfaces.

The metal foil material is flexible and can stretch, allowing it to conform to different shapes. This makes Foil Tapes ideal for sealing, protecting, and repairing curved or irregular surfaces.

For example, aluminium foil tape is commonly used for sealing pipes, insulating cables, and protecting curved parts in the automotive industry.

However, the exact suitability depends on factors like tape thickness, adhesive strength, and the specific shape and size of the surface.

Foil Tapes are highly suitable for shielding electronic devices. Here’s why:

Copper foil tape, for example, is commonly used for electromagnetic shielding. Its excellent conductivity helps block electrical signals, while the added nickel in the adhesive helps shield against magnetic interference.

Conductive fabric tapes, with their excellent shielding properties, are widely used in electronics like computers and mobile phones. They help isolate and block electromagnetic and radio frequency interference, ensuring stable performance during high-frequency transmission.

For instance, 3M™ 3313 conductive copper foil tape uses a conductive acrylic adhesive, which offers strong adhesion and is highly flexible. This makes it ideal for applications like EMI/RFI shielding, flexible flat conductors, and circuit boards.

In summary, Foil Tapes, especially copper foil and conductive fabric tapes, are perfect for providing reliable electromagnetic shielding for electronic devices.

At Jiepu, we offer die-cutting services for these materials, providing precise and tailored solutions to meet your needs.

Foil Tapes can resist some chemical solvents, but it depends on the tape’s material and the type of solvent.

For example, 3M™ Aluminum Foil Tape has an acrylic adhesive that offers some chemical resistance, but this can vary with different solvents.

Aluminium and certain plastics resist some chemicals well, while others might cause damage.

Specific tapes, like 3M™ solvent-resistant labels, can withstand chemicals such as acetone and toluene, protecting printed information.

Overall, the chemical resistance of Foil Tapes depends on the material and the solvent.

For best results, it’s important to check the technical data sheets to ensure the tape is suitable for your specific needs.

At Jiepu, we also provide die-cutting services to tailor solutions for your applications.

The adhesive strength of Foil Tapes improves over time. After applying the tape, the adhesive gradually bonds better with the surface. For example, with 3M™ VHB™ Tape 5907, it reaches about 50% of its final strength within 20 minutes, 90% after 24 hours, and 100% after 72 hours. This means that Foil Tapes can provide strong, long-lasting adhesion.