Die-Cutting Polyurethane Foam (PU Foam)

- Get the perfect Die-Cutting Polyurethane Foam from Jiepu, a reliable Polyurethane Foam Die-Cutting manufacturer from China.

- We will design a custom, cost-effective solution for your business.

- IATF 16949:2016 Certification.

- Low MOQ

- Product Details

- Application Overview

- Material Insights

- Lightweight: Polyurethane Foam foam is very light, making it easy to carry and install.

- Insulation: Its porous structure provides excellent thermal insulation, saving energy effectively.

- Soundproofing: Once cured, it blocks noise and resists moisture, ideal for various environments.

- Durable and Flexible: PU foam is elastic, wear-resistant, and holds up well over long-term use.

- Eco-Friendly: Free of harmful substances, it meets modern environmental safety standards.

- Versatile Applications: Widely used in electronics, cars, furniture, construction, and more.

Jiepu, drawing on years of die-cutting experience, introduces the key characteristics of Polyurethane Foam (PU Foam) that make it a versatile material for many industries:

- Physical Properties: PU Foam is flexible, soft, and pressure-resistant, making it suitable for different shapes and firmness levels.

- Shock Absorption & Soundproofing: Its porous structure absorbs shocks and reduces noise, perfect for protective and soundproof applications.

- Weather & Corrosion Resistance: PU Foam can withstand harsh environments, offering excellent resistance to weather and corrosion.

- Easy to Process: PU Foam is easy to cut and shape using die-cutting, moulding, and other techniques.

- Lightweight: With its low density, PU Foam is easy to handle and transport.

- Durability: It resists wear and tear, keeping its shape and function over time.

- Thermal Insulation: PU Foam offers good insulation, ideal for keeping items hot or cold.

- Eco-friendly: It contains no harmful substances, meeting modern environmental standards.

Custom Die-Cutting with Polyurethane Foam

At JIEPU, we specialise in custom die-cutting services tailored to your specific needs. Whether for automotive electronics, security systems, or other industries, we offer precise solutions that meet your product requirements. Our range of materials includes Polyurethane Foam, which provides excellent cushioning, insulation, and impact protection.

With a focus on personalised design, accurate cutting, and fast delivery, we offer flexible solutions for both small and large production runs. JIEPU helps you improve product quality, reduce costs, and accelerate time to market.

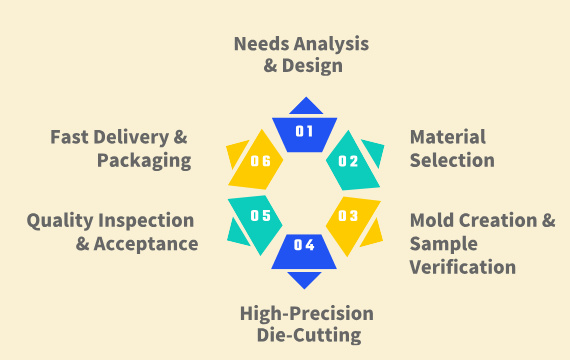

Polyurethane Foam Die-Cutting Process

At Jiepu, we often work with polyurethane foam in various applications.

The process starts by selecting the right type of foam, such as flexible, rigid, or microcellular polyurethane foam, each with unique properties like bounce, softness, or breathability.

After checking the material’s quality, we design the mould and use die-cutting methods, like flatbed or rotary, to shape the foam.

Depending on the requirements, further steps like punching or adding adhesives may be done to meet customer needs.

Certified PU Foam Die-Cutting Services

Jiepu provides PU foam die-cutting services that meet ISO 9001, ISO 14001, and IATF 16949 standards.

Our products are eco-friendly, reliable, and meet the specific needs of industries like automotive.

We offer custom solutions with excellent properties like shock absorption, sound insulation, and thermal resistance, ensuring high-quality and sustainable results.

How to Request Samples and Get a Quote for Polyurethane Foam

At Jiepu, with over 20 years of experience in die-cutting, we simplify the process of getting Polyurethane Foam to suit your needs. Here’s how it works:

1. Share Your Requirements

Tell us about your foam needs—density, hardness, size, and shape.

2. Request a Sample

You can ask for samples to test and check if they meet your needs. Some companies also offer sample packs to help with your choice.

3. Material Selection

Choose between polyester-based or polyether-based foam. This decision affects the foam’s properties and its best use.

4. Custom Design

We’ll design the Polyurethane Foam to fit your exact size and shape needs.

5. Getting a Quote

After you provide details, we’ll calculate material costs and processing fees, then send you a clear quote.

6. Sample Production and Testing

We create samples for you to test, ensuring they meet your performance requirements. Custom options like backing fabrics or heat treatments can be included.

7. Bulk Production

Once the sample passes testing, you can place an order for bulk production. We’ll organise production based on order volume and delivery deadlines.

8. Quality Control and Certification

We perform strict quality checks and provide necessary certifications like RoHS to ensure your product meets environmental and safety standards.

9. After-Sales Support

We offer professional, comprehensive after-sales service to ensure you are satisfied with your product.

10. Storage Conditions

Store your Polyurethane Foam in a stable environment, maintaining the right temperature and humidity for optimal performance.

11. Special Requirements

If you have specific needs, like temperature resistance or chemical resistance, let us know, and we will tailor the product accordingly.

12. Eco-Friendly Compliance

Our Polyurethane Foam meets RoHS compliance, ensuring no harmful substances are used.

By following these steps, you can be sure that you’ll get the Polyurethane Foam that’s right for your project, with the right performance, quality, and compliance.

Polyurethane foam is a lightweight material made from polyurethane, which is created by mixing two chemicals, usually a type of alcohol and an acid, with other ingredients to form a foam. It’s well-known for being soft, yet strong, and is used in many different industries.

It’s light, making it easy to transport and install, and it’s elastic, offering good support and comfort. Its closed-cell structure also makes it great for insulation, helping to keep things warm or cool. The material is durable, resistant to wear and tear, and can be made in different densities and hardness to suit various needs. Additionally, some types are eco-friendly and can be recycled.

Polyurethane foam is used in furniture like mattresses and seats, building insulation, car interiors, footwear, clothing, and packaging. At Jiepu, we offer die-cutting services, which can help customise the foam to fit your exact requirements.

The lifespan of polyurethane foam can vary depending on factors like the quality of the material, how it’s used, and how well it’s maintained. Under normal conditions, polyurethane foam can last for over 10 years. Some types, like polyurethane foam used in insulation pipes, can last 30 to 50 years if properly installed. For foam used in sealing, high-quality versions can remain in good condition for several years without ageing or deforming.

In general, polyurethane foam can last between 15 and 20 years, but the actual lifespan will depend on the specific environment and use. At Jiepu, we offer die-cutting services that can customise foam to your needs, ensuring optimal performance for its intended lifespan.

When choosing the right polyurethane foam for automotive products, you need to think about several factors. The foam’s physical properties, durability, environmental impact, and cost all play a role. Here are the main points to consider:

You should match the foam’s density and hardness to the specific parts of the car. For example, seating areas need foam that bounces back easily, while structural parts require denser foam for better support.

Durability and resistance to wear are also important. You’ll want foam that doesn’t break down quickly, ensuring long-term performance.

Environmental impact matters, too. Choose foam with low VOC emissions and no harmful substances to help with air quality and meet regulations.

For noise reduction, select foam with good sound absorption properties, which is crucial for parts like engine covers and carpets.

As the automotive industry pushes for lighter vehicles, low-density foam can help reduce weight and improve fuel efficiency.

The foam should be able to handle temperature changes. It needs to stay stable in both hot and cold conditions.

For safety, especially in seats and interior parts, choose fire-resistant foam.

The foam should also be easy to shape and process to fit complex designs in the car.

Cost is always a consideration. Find foam that balances good performance with affordability.

Finally, working with suppliers who offer strong technical support is crucial. You’ll want help with maintenance and problem-solving if anything goes wrong.

At Jiepu, we provide die-cutting services to help shape polyurethane foam to meet your needs. With years of experience, we can help you choose the right materials for your automotive products.

Polyurethane foam is an environmentally friendly material in several ways. Firstly, its production uses more eco-friendly raw materials, particularly with the choice of blowing agents that avoid harmful substances. Additionally, the foam can be modified with bio-based materials like chitosan, lignin, and cellulose, which are renewable and green. Polyurethane foam is also known for its chemical stability, making it a great insulator with low thermal conductivity, improving energy efficiency. It has become popular in applications like waste treatment and noise reduction. Research is ongoing into its biodegradability and ecological impact to ensure safety in the environment.

At Jiepu, we specialise in die-cutting services and can help customise polyurethane foam for your needs.