Customized Die Cutting Thermal Conductive Silicone Solution

- High-Quality Thermal Conductive Silicone Solution at Competitive Prices

- ISO9001 & ISO14001 Certification

- Over 20 years of Die Cutting experience

- Quick Samples from China

- Product Details

- Application Overview

- Material Insights

- Thermal Conductive Silicone quickly transfers heat to improve cooling efficiency, with thermal conductivity ranging from 1.5 to 12W/M.K.

- Offers excellent electrical insulation, ensuring safe use in applications requiring electrical protection.

- Its softness and compressibility allow it to fill gaps and irregular surfaces, ensuring maximum heat transfer.

- Works reliably in temperatures from -40°C to 180°C, maintaining consistent performance over time.

- Resists corrosion from common chemicals and environmental factors, extending the product’s lifespan.

- Compliant with global environmental standards, ensuring safe use and minimal environmental impact.

Jiepu, with its extensive die-cutting experience, presents the key characteristics of thermal conductive silicone.

- Composition and Structure: Made from silicone rubber polymers, like PDMS, with added fillers such as ceramics or metals to enhance heat conductivity.

- Temperature and Environment: Its heat conductivity can change with temperature, humidity, and pressure, so it’s important to consider these factors.

- Thickness and Shape: Thinner materials generally transfer heat better, and shapes can affect the heat flow.

- Surface Treatment and Contact Resistance: The smoothness of the surface and contact resistance affect heat transfer, especially in cooling pads or heat sinks.

- Heat Conductivity Range: Typically, thermal silicone has a conductivity of 0.1 to 0.4 W/m·K, lower than metals but higher than most plastics.

- Comparison with Other Materials: It has better heat conductivity than most plastics and rubbers but lower than metals like copper or aluminium.

- Thermal Stability and Reliability: It works well in a wide temperature range, from -50°C to over 200°C, making it ideal for both hot and cold environments.

- Challenges and Limitations: Despite its advantages, its lower thermal conductivity compared to metals limits its use in applications needing extreme heat dissipation.

Customised Thermal Conductive Silicone Solutions

At Jiepu, we specialise in providing customised die-cut solutions, including high-quality Thermal Conductive Silicone, tailored to your specific needs. Whether you’re in automotive electronics, security, or any other industry, we offer precise design, a range of materials, and accurate cutting. Our services help improve your product’s performance, reduce costs, and speed up production, with quick delivery and flexible solutions for both small and large-scale orders.

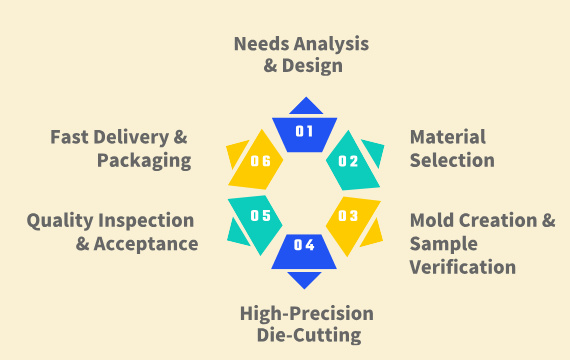

Thermal Conductive Silicone Die Cutting Process

At Jiepu, we often apply a straightforward approach for cutting Thermal Conductive Silicone.

First, we choose materials like silicone rubber mixed with thermal fillers such as aluminium oxide or boron nitride, ensuring excellent heat transfer.

We then design the die to match the required shape and size. The material is cut using either flatbed or rotary methods, depending on thickness, and may involve additional steps like perforating for more complex shapes.

Certified Excellence in Die-Cutting Services

At Jiepu, we take pride in delivering top-notch die-cutting solutions, supported by international certifications.

With ISO 9001, we ensure consistent quality and customer satisfaction. ISO 14001 reflects our commitment to environmental care and resource efficiency. Additionally, IATF 16949 demonstrates our expertise in meeting the automotive industry’s strict standards.

Explore More Die Cutting Materials

Thermal Conductive Silicone Die-Cutting Samples and Quotation Process

At Jiepu, we make requesting samples and getting quotes for Thermal Conductive Silicone easy and efficient. Here’s how it works:

- Initial Contact: Our online team will learn about your project type, quantity, and timeline, then assign a dedicated technical engineer for one-on-one support.

- Custom Recommendations: Based on your application and budget, we’ll suggest the best adhesive solutions. You can provide material models or product drawings for free sampling.

- Drawing Confirmation: We’ll review your product drawings, material type, and thickness to ensure precise pricing and processing.

- Quotation: After confirming the details, we’ll offer a tailored process plan and pricing. Quantity affects the pricing, with discounts for larger orders.

- Order Confirmation: Once you approve the quote, we’ll laser cut a sample within 24 hours. After your approval, we’ll move to small-scale production.

- Contract Signing: We provide contract templates or accept your standard agreement to streamline the process.

- Payment: We support various payment methods and offer monthly billing options for regular orders.

- Mass Production: After all steps are completed, we’ll proceed with large-scale production to meet your needs.

This straightforward process ensures accuracy and efficiency from start to finish. Have questions? Our team is here to help!

![]()

Thermal Conductive Silicone is a soft silicone material that helps to transfer heat efficiently. It is mainly used in electronics to improve cooling.

The material is made from silicone rubber and heat-conducting fillers like aluminium oxide, silicon oxide, or boron nitride.

It has several key features:

- It transfers heat effectively, moving heat away from components to cooling parts.

- It is electrically insulating, which helps prevent electrical shorts.

- It is flexible, which allows it to adapt to different surfaces and fill gaps for better heat contact.

- It can work in a wide range of temperatures, making it versatile.

- It is durable, resistant to ageing and chemicals, and lasts a long time.

- It is safe, non-toxic, and meets environmental standards.

Thermal Conductive Silicone is often used in CPUs, GPUs, LED lights, and power modules to improve heat management. It can be applied in the form of paste, pre-formed pads, or tapes. Jiepu also provides die-cutting services for custom applications.

Thermal conductive silicone transfers heat effectively, and its performance is measured by its thermal conductivity.

The higher the thermal conductivity, the better it can conduct heat.

The performance depends on several factors:

- The type of filler material, like metal oxides or carbon, helps improve heat transfer.

- The more filler material it contains, the better the heat conduction, as these fillers conduct heat better than silicone alone.

- The silicone base itself has lower conductivity, but with the right fillers, the overall performance improves.

- Different formulations and manufacturing processes also impact performance.

- The thinner the material, the better it typically performs in heat conduction.

- Applying pressure helps improve the contact between the silicone and the surface, enhancing heat transfer.

- Temperature and environmental factors, like humidity, can also affect its performance.

- Thermal conductive silicone generally ranges from 0.5 to 8 W/m·K, depending on these factors.

At Jiepu, we can customise die-cut thermal conductive silicone for your specific needs, ensuring optimal heat management.

Thermal conductive silicone and metal thermal pads each have their strengths and weaknesses:

- Thermal conductive silicone is soft and can fill small gaps, providing good flexibility.

- Metal thermal pads are rigid but offer better heat transfer in some cases.

- Silicone pads are easy to install and can be pre-cut to size, while metal pads may need more adjustments.

- Silicone also has excellent insulation properties, unlike metal pads that conduct electricity.

- While silicone pads are more durable over time, metal pads can corrode or degrade.

- However, metal pads generally have a higher thermal conductivity, meaning better heat transfer in some applications.

- Silicone pads are lighter and can be reused, whereas metal pads may be harder to remove.

- Metal pads have a wider temperature tolerance, but silicone performs better in extreme environments.

At Jiepu, we provide die-cutting services to help with customising thermal pads and ensuring the right fit for your needs.

Thermal conductive silicone typically has a long lifespan, often lasting between 5 to 10 years, or even longer, depending on the conditions.

It remains stable over time, maintaining good heat transfer properties in different environments.

The material is resistant to chemicals and high temperatures, allowing it to function well between -40°C and 180°C, which helps extend its life.

However, factors like storage, manufacturing process, and the environment where it’s used can affect its durability.

In harsh conditions, such as extreme heat, humidity, or chemical exposure, its performance may degrade, shortening its lifespan.

Improper use, like bending, stretching, or excessive force, can also lead to early failure.

Overall, thermal conductive silicone is a durable and stable material, lasting long under normal conditions. At Jiepu, we offer die-cutting services to ensure the perfect fit for your needs.

Thermal Conductive Silicone is a highly efficient material, but it tends to be slightly more expensive compared to other materials like thermal paste. However, its cost-effectiveness is notable.

It offers high thermal conductivity, low thermal resistance, insulation, and compressibility, all of which improve heat transfer while reducing air gaps between surfaces. This helps enhance overall thermal performance.

Thermal Conductive Silicone’s adjustable thermal conductivity and stable heat dissipation make it reliable for long-term use, reducing the need for equipment replacements due to poor cooling and lowering overall costs.

Its lifespan is typically around 10 years, making it a durable option for many electronic devices. Its resistance to aging and good insulation properties add to its long-term reliability.

Though its temperature range is slightly lower than thermal pastes, it still meets the cooling needs of most electronics. Additionally, it is easy to apply, either manually or with machines, ensuring efficiency.

Thermal Conductive Silicone is also environmentally friendly, made from safe materials that meet international standards like RoHS and REACH, ensuring safety for both users and the environment.

In summary, while it may require a higher initial investment, the long-term stability, reliability, and environmental benefits make Thermal Conductive Silicone a cost-effective choice. At Jiepu, we provide die-cutting services for custom applications of such materials, ensuring precise fits for your needs.