Your Specialist For Die-Cutting Thermal Tapes

- Top-Notch Die-Cutting Thermal Tapes Production Standards

- ISO14001 Certified Die-Cutting Production

- 3-day rapid production of samples

- MOQ 100Pcs

- Product Details

- Application Overview

- Material Insights

- Thermal Tapes use materials like ceramic particles to ensure efficient heat transfer.

- Improves heat transfer from the source to the heat sink efficiently.

- Some Thermal Tapes provide both heat conduction and electrical insulation for electronics.

- Thermal Tapes offer cushioning and act as a heat-conducting material simultaneously.

- Meets ROHS and REACH standards, making it safe and environmentally friendly.

- Performs well in hot and humid conditions, ideal for demanding environments.

- Thermal Silicone Sheets: These flexible sheets are made from silicone rubber and thermal fillers, perfect for filling gaps and providing efficient heat transfer on uneven surfaces.

- Thermal Putty: A moldable material that adapts to shapes and fills gaps, offering custom thermal management solutions.

- Thermal Gel: This gel conforms to surfaces, filling holes and staying in place when cured, making it easy to handle and use.

- Thermal Double-Sided Adhesive: A sticky tape that efficiently bonds heat sources and heat sinks, ideal for automated production lines.

- Graphene Thermal Sheets: Made from graphite, these sheets are excellent at spreading heat across surfaces, especially in devices like smartphones and laptops.

- Phase Change Materials (PCM): These materials change state with heat, filling gaps when soft, making them ideal for applications needing adaptability to heat changes.

Tailored Thermal Tapes for Your Unique Needs

At Jiepu, we offer customised die-cut solutions, including high-performance Thermal Tapes, to meet the specific needs of your business. Whether it’s automotive electronics, security, or other industries, our services include personalised design, a wide range of materials, precise cutting, and fast delivery. We adapt to your requirements, helping you improve product quality, reduce costs, and speed up time-to-market.

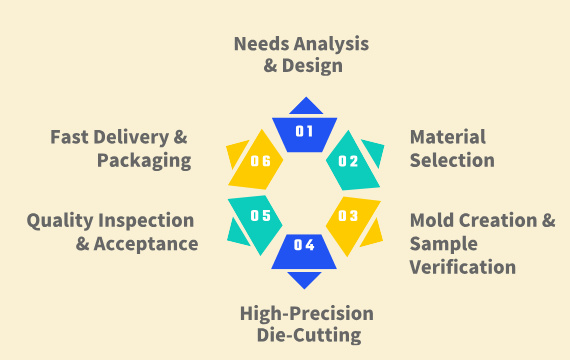

Thermal Tapes Die Cutting Process

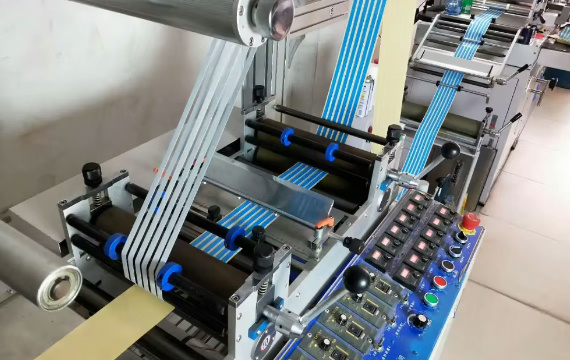

At Jiepu, we often use a precise die cutting process for Thermal Tapes.

First, we select materials like polyimide films or aluminium foils with added thermal conductive powders to ensure excellent heat dissipation.

After choosing the right material, we design and create the die, ensuring it’s suited to the tape’s size and material type.

The tape is then cut using either flatbed or rotary methods, depending on thickness. Additional steps like perforating or shaping may be needed for complex designs.

Custom Die-Cutting with Thermal Tapes You Can Rely On

At Jiepu, we combine advanced die-cutting expertise with high-quality Thermal Tapes to deliver reliable solutions. Certified to ISO 9001, ISO 14001, and IATF 16949 standards, we ensure exceptional quality, environmental care, and industry-specific precision.

Our Thermal Tapes provide excellent heat transfer for electronics, automotive, and medical devices, maintaining performance and stability. We offer custom sizes and shapes to suit your exact needs, ensuring efficiency and reliability in every application.

Explore More Die Cutting Materials

Simplified Samples and Quotation Process for Thermal Tapes Die-Cutting Services

At Jiepu, with over two decades of expertise, we understand that getting the right thermal tapes for your project can be a bit tricky. Here’s how we make it simple and easy for you:

- Drawing Approval: We check if your design can be made in bulk without issues. We prefer using common materials that are easy to get. You just need to send us all the 2D drawings, and we’ll handle the rest.

- Material Check: We ensure we have all the materials ready and use standard ones to avoid delays.

- Process Review: Our team looks at the best way to make your sample and checks if any special holes or marks are needed for positioning.

- Pricing: We know the cost of materials and different making methods. Prices depend on how much you need and how complex the job is. For bigger orders, we might even give back the tooling fee after production starts.

- Sample Creation: With your detailed instructions, we create a perfect sample within 3 days, using the exact materials and sizes you want.

- Quality Check: Our quality team measures everything and gives you a report. We then send the samples to you quickly.

- Final Docs: Before full production, we gather all necessary documents like material certificates and testing reports for your review.

- Production and Delivery: Once you approve the sample, we start making your order. Our team keeps an eye on quality throughout. After everything is ready, we pack and deliver your products.

- After-Sales Support: We stay in touch to make sure everything goes smoothly when you use our thermal tapes in your projects.

Thermal tapes are special tapes designed to help transfer heat from one component to another. They are widely used in electronics and other devices that generate heat.

The tape is made of layers that include a heat-conducting layer and an adhesive. It easily attaches to parts like heat sinks or cooling components by peeling off the backing and sticking it in place.

Thermal tapes improve cooling, make devices work better, and help them last longer. Jiepu offers die-cutting services to customise these tapes for your specific needs.

Thermal tape works by transferring heat efficiently between components to keep devices cool.

It fills small air gaps between parts like electronic chips and heat sinks, which can block heat flow. The heat-conducting layer in the tape moves heat quickly to cooling areas.

The adhesive layer ensures the tape sticks firmly, creating a smooth path for heat transfer. This reduces heat build-up, improving device performance and lifespan.

Thermal tape is stable under high temperatures and easy to apply. At Jiepu, we offer die-cutting services to customise thermal tapes for your specific needs.

Thermal tape is designed for heat transfer, while regular tape is for basic sticking tasks.

Thermal tape uses special heat-conducting materials to move heat between components. Regular tape doesn’t transfer heat and is made from non-conductive materials.

Thermal tape works well in high temperatures and some types can also insulate against electricity. Regular tape might lose its stickiness or deform when exposed to heat.

Thermal tape is used in electronics and devices to manage heat. Regular tape is for everyday uses like sealing or fixing.

Jiepu provides die-cutting services to customise thermal tapes for your needs, making them perfect for precise applications.

To avoid air bubbles when applying thermal tape, here are some simple tips:

- Clean the surface thoroughly to remove dust, oil, or dirt for better adhesion.

- Use a tape thickness that suits your needs; thicker tapes often reduce air bubbles.

- Press the tape evenly using a roller or tool to push out trapped air.

- Avoid stretching the tape during application, as it can create pockets of air.

- Peel off the protective liner slowly to prevent air from getting trapped.

- Work in a clean, dust-free environment for the best results.

At Jiepu, we also offer die-cutting services to ensure your thermal tape fits perfectly, making application even easier.