Custom Your Die-Cutting VHB Foam Tapes

- As a VHB Foam Tape Die-Cutting factory, Jiepu specializes in customizing VHB Foam Tapes

- 3-day rapid production of samples

- IATF 16949:2016 Certification

- Low MOQ

- Product Details

- Application Overview

- Material Insights

- VHB Foam Tapes create strong bonds, replacing screws, rivets, and welding.

- They perform well in high temperatures and humid environments.

- VHB Foam Tapes resist solvents and salt spray, staying strong in extreme conditions.

- Their flexibility absorbs loads and handles material expansion differences.

- Using VHB Foam Tapes reduces structure weight by replacing heavier fasteners.

- VHB Foam Tapes adhesion gets stronger over time for durable performance.

Jiepu, with years of die-cutting experience, has provided die-cutting services across various industries using VHB Foam Tapes, known for their strong adhesive power and versatile applications.

- Building Industry: VHB Foam Tapes are used to fix large glass panels on buildings like the Burj Al Arab in Dubai and the Disney Concert Hall, replacing screws and welds.

- Automotive Industry: VHB Foam Tapes bond and seal car parts, offering reliable performance in both high and low temperatures.

- Solar Industry: VHB Foam Tapes secure and seal solar panel modules, providing waterproofing and long-lasting protection.

- Elevator Industry: VHB Foam Tapes are used to secure reinforcement bars, mirrors, and decorative panels in elevators.

- Electronics Industry: In electronics, VHB Foam Tapes are used to attach screens and labels, offering shock absorption and waterproofing.

- Advertising Industry: VHB Foam Tapes are also used to securely fix signs and displays in advertising applications.

- Acrylic Foam Structure: The tape’s core is made from 100% closed-cell acrylic foam, providing strong bonding, long-lasting durability, and excellent waterproof sealing.

- Viscoelasticity: The tape’s unique combination of elasticity and stickiness allows it to bond strongly under dynamic stress while relaxing under static stress.

- Full Acrylic Composition: The acrylic foam core and adhesive layers are made of a special material that absorbs stress, helping to protect the bond and improve durability.

- Aging Resistance: VHB Foam Tapes resist UV and heat damage, becoming even stronger over time to maintain a long-lasting bond.

- High Adhesion Strength: The tape can bond various materials, handling thermal expansion and stress, and protecting surfaces from chemical or electrical corrosion.

Custom Die-Cutting with VHB Foam Tapes

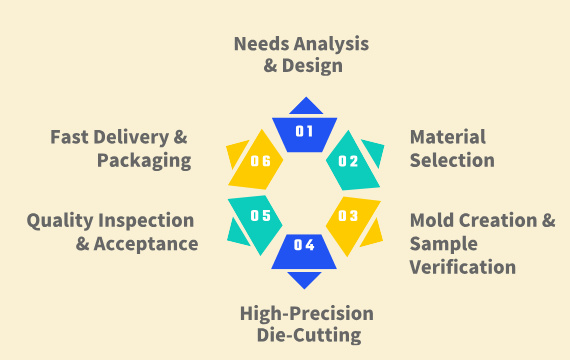

At JIEPU, we specialise in custom die-cutting solutions tailored to meet your specific needs. Whether your business operates in automotive electronics, security, or other industries, we offer high-precision and high-quality services. We provide a range of materials, including VHB Foam Tapes, known for their strong adhesion and ability to withstand tough conditions.

Our services include personalised design, precise cutting, and fast delivery, ensuring that we meet both small and large production requirements. JIEPU helps you improve product quality, reduce costs, and accelerate time to market.

Die-Cutting Process for VHB Foam Tapes

We specialise in die-cutting VHB Foam Tapes, a high-performance adhesive material known for its excellent bonding strength and weather resistance.

The process begins by selecting the right foam tape, followed by a thorough quality check to ensure smooth surfaces and consistent edges.

We then design and manufacture precise cutting tools, carefully considering the tape’s thickness and adhesive properties, ensuring efficient and accurate die-cutting results.

Certified VHB Foam Tape Die-Cutting Services

Jiepu’s VHB Foam Tape die-cutting services are fully certified with ISO 9001, ISO 14001, and IATF 16949 standards.

This ensures top-quality products that meet automotive industry requirements and are eco-friendly.

VHB Foam Tapes offer strong adhesion, elasticity, and weather resistance, providing reliable solutions for various applications with custom cutting options.

Expanded Die Cutting Material Inventory

VHB Foam Tapes: Simple Steps for Sample Request and Quotation

At Jiepu, with over 20 years of experience in die-cutting, we’ve made the process of requesting VHB Foam Tapes samples and quotes as simple as possible. Here’s how it works:

1. Share Your Requirements

Let us know the size, thickness, adhesive strength, and application of the VHB Foam Tapes you need.

2. Request Samples

You can ask for samples to test and verify the product. We will make an initial sample based on your drawings or specifications.

3. Confirm Drawings and Process Design

We will review the drawings to ensure they are ready for mass production. We also design the process to avoid any production issues while maintaining consistent quality.

4. Get Your Quote

We will calculate the cost based on material, production, and processing. Our technical team handles the material costs, while the finance team covers manufacturing and other overheads.

5. Sample Production and Testing

Once the sample is made, you can test it to ensure it meets your requirements. Customisation options like fabric backing or heat treatment are available.

6. Mass Production

After testing and approval, we begin bulk production based on your order quantity and delivery date.

7. Quality Control and Certification

We perform strict quality checks and provide necessary certifications (like RoHS) to ensure environmental and safety standards are met.

8. After-Sales Service

Our service continues even after delivery. We offer complete after-sales support to resolve any issues quickly.

9. Storage Conditions

To maintain the quality and performance of VHB Foam Tapes, we recommend storing them in a controlled environment with the right temperature and humidity.

10. Special Requirements

If you have specific needs, such as particular temperature ranges or shielding properties, please share them so we can customise the product accordingly.

11. Environmental Compliance

We ensure all VHB Foam Tapes are RoHS compliant, meaning they contain no harmful substances.

12. Customisation Services

We offer customisation services such as lamination and combining different foam types based on your specifications.

By following these steps, you can be confident that the VHB Foam Tapes you receive will meet your exact needs, with reliable performance and high quality.

VHB Foam Tape is a high-performance double-sided tape made from a core of acrylic foam, with strong acrylic adhesive on both sides.

Known for its “Very High Bond” strength, it offers exceptional bonding power, durability, and flexibility.

This tape is widely used in industries like automotive, consumer electronics, and security, providing long-lasting adhesion, weather resistance, temperature tolerance, and impact resistance.

Jiepu, with its expertise in die-cutting, can provide customised VHB foam tape solutions for your needs.

VHB Foam Tapes offer excellent bonding strength. They provide a long-lasting, strong bond for a wide range of materials. For example, the tape can withstand a peel strength of 12.3 N/cm (measured at 180° according to ASTM D3330) and a shear strength of 550 kPa on stainless steel. It also has a tensile strength of 690 kPa on aluminium at 22°C. These strong properties make VHB Foam Tapes suitable for many different applications and environments.

At Jiepu, we offer die-cutting services that can tailor these tapes to fit your specific needs.

The adhesive strength of VHB Foam Tapes improves over time. According to 3M, after 20 minutes, the bond reaches about 50% of its final strength.

After 24 hours, it is around 90%, and after 72 hours, it reaches 100%. This shows that the tape offers long-lasting adhesive performance that strengthens with time.

VHB Foam Tapes help with sealing and shock absorption in automotive interiors in several key ways:

The tapes securely bond interior and exterior parts to the car body, providing a strong seal.

They also help reduce weight by replacing traditional fastening methods like screws and welding, all while offering sealing benefits.

With their powerful adhesive, VHB tapes bond firmly to surfaces, even smooth plastics and metals.

They work as an excellent filler, blocking moisture, dust, and chemicals for a reliable seal.

The tapes are highly durable, resisting temperature changes and extreme conditions, ensuring long-lasting performance.

VHB Foam Tapes are also shock-resistant, help reduce noise, and improve comfort by damping vibrations.

Additionally, they are resistant to UV rays and solvents, providing long-term sealing and protection.

At Jiepu, we offer die-cutting services to create custom VHB Foam Tape solutions for your specific needs.